Page 318 - IJB-10-5

P. 318

International Journal of Bioprinting Amphiphobic encap. for transient devices

2.7. Device-level demonstration 3. Results and discussion

Schematic diagrams for the flexible printed circuit

board (fPCB) and the board layout were designed using 3.1. 3D printing of the polyanhydride

AUTODESK EAGLE (version 9.6.2). The components encapsulation layer

included a red LED (IN-S63ASR; Inolux, USA), 0402-in. Our 3D printing technique utilizes the DLP principle,

footprint capacitors, and six-turn double-layered coils for which involves dispersing the PBTPA solution and

wireless power transferring (resonant frequency: 13.56 applying UV irradiation to create an optimized unit layer

MHz). All components were mounted onto the fPCB with 50 μm thickness. We achieved the desired thickness

manufactured by an ISO-9001-compliant vendor, using of PBTPA by dividing it into thin unit layers, resulting in

solder paste (SMDLTLFP; Chip Quik, USA). The device superior waterproofing properties through both physical

measured 11 mm in width and 9 mm in length. The fPCB and chemical means (Figure 1). The layer-by-layer 3D

device, including the LED, was embedded in 1% agarose, printing process isolates polymer defects in each layer. The

containing PBS, and stored in a 37°C oven. decoupled defects in the unit layer increase the effective

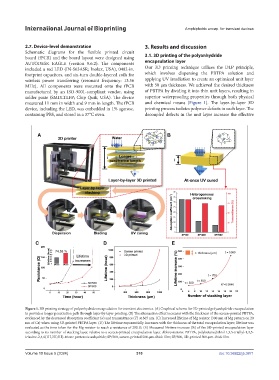

Figure 1. 3D printing strategy of polyanhydride encapsulation for transient electronics. (A) Graphical scheme for 3D-printed polyanhydride encapsulation

to provide a longer penetration path through layer-by-layer printing. (B) The attenuation effect increases with the thickness of the screen-printed PBTPA,

evidenced by the decreased absorption coefficient (α) and transmittance (T) at 365 nm. (C) Increased lifetime of Mg resistor (300 nm of Mg pattern on 20

nm of Cr) when using 3D-printed PBTPA layer. (D) The lifetime exponentially increases with the thickness of the total encapsulation layer; lifetime was

evaluated as the time taken for the Mg resistor to reach a resistance of 200 Ω. (E) Measured lifetime increase (%) of the 3D-printed encapsulation layer

according to its number of stacking layer, relative to a screen-printed encapsulation layer. Abbreviations: PBTPA, polybutanedithiol 1,3,5-triallyl-1,3,5-

triazine-2,4,6(1H,3H,5H)-trione pentenoic anhydride; SP/500, screen-printed 500-μm-thick film; 3P/500, 3D-printed 500-μm-thick film.

Volume 10 Issue 5 (2024) 310 doi: 10.36922/ijb.3871