Page 435 - IJB-10-5

P. 435

International Journal of Bioprinting Bioprinting for large-sized tissue delivery

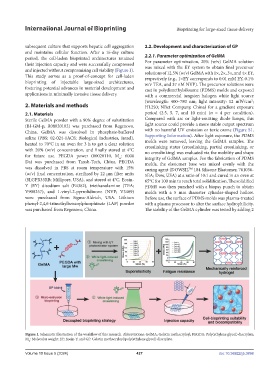

subsequent culture that supports hepatic cell aggregation 2.2. Development and characterization of GP

and maintains cellular function. After a 16-day culture

period, the cell-laden bioprinted architectures retained 2.2.1. Parameter optimization of GelMA

their injection capacity and were successfully compressed For parameter optimization, 20% (w/v) GelMA solution

was mixed with the EY system to obtain final precursor

and injected without compromising cell viability (Figure 1). solutions of 12.5% (w/v) GelMA with 1×, 2×, 3×, and 4× EY,

This study serves as a proof-of-concept for cell-laden respectively (e.g., 1×EY corresponds to 0.01 mM EY, 0.1%

bioprinting of injectable large-sized architectures, w/v TEA, and 37 nM NVP). The precursor solutions were

fostering potential advances in material development and cast in polydimethylsiloxane (PDMS) molds and exposed

applications in minimally invasive tissue delivery. with a commercial tungsten halogen white light source

(wavelength: 400–780 nm; light intensity: 12 mW/cm ;

2

2. Materials and methods HL250; NBet Company, China) for a gradient exposure

2.1. Materials period (2.5, 5, 7, and 10 min) (n = 4 per condition).

Sterile GelMA powder with a 90% degree of substitution Compared with arc or light-emitting diode lamps, this

(BI-GM-p, R08020102) was purchased from Regenovo, light source could provide a more stable output spectrum

China. GelMA was dissolved in phosphate-buffered with no harmful UV emission or toxic ozone (Figure S1,

saline (PBS; 02-024-1ACS; Biological Industries, Israel), Supporting Information). After light exposure, the PDMS

heated to 70°C in an oven for 3 h to get a clear solution molds were removed, leaving the GelMA samples. The

crosslinking status (crosslinking, partial crosslinking, or

with 20% (w/v) concentration, and finally stored at 4°C no crosslinking) was evaluated via the mobility and shape

for future use. PEGDA power (80020110, M : 6000 integrity of GelMA samples. For the fabrication of PDMS

w

Da) was purchased from Tansh-Tech, China. PEGDA molds, the elastomer base was mixed evenly with the

was dissolved in PBS at room temperature with 15% curing agent (DOWSIL 184 Silicone Elastomer, 761036-

TM

(w/v) final concentration, sterilized by 22 μm filter units 5EA; Dow, USA) at a ratio of 10:1 and cured in an oven at

(SLGPR33RB; Millipore, USA), and stored at 4°C. Eosin- 65°C for 100 min to reach total solidification. The solidified

Y (EY) disodium salt (E4382), triethanolamine (TEA; PDMS was then punched with a biopsy punch to obtain

V900257), and 1-vinyl-2-pyrrolidinone (NVP; V3409) molds with a 5 mm diameter cylinder-shaped hollow.

were purchased from Sigma-Aldrich, USA. Lithium Before use, the surface of PDMS molds was plasma-treated

phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) powder with a plasma processor to alter the surface hydrophilicity.

was purchased from Regenovo, China. The stability of the GelMA cylinder was tested by adding 2

Figure 1. Schematic illustration of the workflow of this research. Abbreviations: GelMA: Gelatin methacryloyl; PEGDA: Poly(ethylene glycol) diacrylate;

M : Molecular weight; EY: Eosin-Y; and GP: Gelatin methacryloyl/poly(ethylene glycol) diacrylate.

w

Volume 10 Issue 5 (2024) 427 doi: 10.36922/ijb.3898