Page 13 - AC-2-4

P. 13

Arts & Communication Tech revitalization of Yakshagana artifacts

A B C D

Figure 6. Variety of headdresses in Badaguthittu Yakshagana: (A) Crown (kireeta) type; (B) kedagemundale type; (C) mundasu type; and (D) bannada

kireeta type

A B C In the domain of musical instruments, the scarcity of

appropriate wooden raw materials and the complexity

in processing leather membranes and tuning them to

the required tension levels during production are major

problems. In fact, artists frequently struggle to tune the

instruments to the required pitch during performance,

and these instruments are prone to atmospheric conditions

such as temperature and humidity. To address these issues,

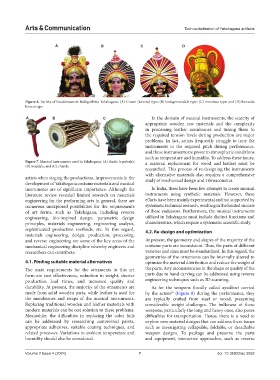

Figure 7. Musical instruments used in Yakshagana: (A) thaala (cymbals); a material replacement for wood and leather must be

(B) maddale; and (C) chande

researched. This process of re-designing the instruments

with alternative materials also requires a comprehensive

artists when staging the productions. Improvements in the study of mechanical design and vibroacoustics.

development of Yakshagana costume materials and musical

instruments are of significant importance. Although the In India, there have been few attempts to create musical

literature review revealed limited research on materials instruments using synthetic materials. However, these

engineering for the performing arts in general, there are efforts have been mainly experimental and not supported by

numerous unexplored possibilities for the requirements systematic technical research, resulting in the limited success

of art forms, such as Yakshagana, including reverse of these endeavors. Furthermore, the musical instruments

engineering, bio-inspired design, parametric design utilized in Yakshagana must include distinct functions and

principles, materials engineering, engineering analysis, characteristics, which require a systematic scientific study.

sophisticated production methods, etc. In this regard, 4.2. Re-design and optimization

materials engineering, design, production, processing,

and reverse engineering are some of the key areas of the At present, the geometry and shapes of the majority of the

mechanical engineering discipline whereby engineers and costume parts are inconsistent. Thus, the parts of different

researchers can contribute. varieties and sizes must be standardized. In this regard, the

geometries of the ornaments can be internally altered to

4.1. Finding suitable material alternatives optimize the material distribution and reduce the weight of

The main requirements for the ornaments in this art the parts. Any inconsistencies in the shape or quality of the

form are cost effectiveness, reduction in weight, shorter parts due to hand carving can be addressed using reverse

production lead times, and increased quality and engineering techniques such as 3D scanning.

durability. At present, the majority of the ornaments are As for the weapons (locally called ayudhas) carried

made from solid wooden parts, while leather is used for by the actors (Figure 8) during the performance, they

20

the membranes and straps of the musical instruments. are typically crafted from steel or wood, presenting

Replacing traditional wooden and leather materials with considerable weight challenges. The bulkiness of these

modern materials can be one solution to these problems. weapons, particularly the long and heavy ones, also poses

Meanwhile, the difficulties in replacing the color foils difficulties for transportation. Hence, there is a need to

can be addressed by researching customized paints, explore new material designs that can address these issues

appropriate adhesives, suitable coating techniques, and such as investigating collapsible, foldable, or detachable

related processes. Variations in ambient temperature and weapon designs. To package and preserve the parts

humidity should also be considered. and equipment, interactive approaches, such as reverse

Volume 2 Issue 4 (2024) 7 doi: 10.36922/ac.3052