Page 61 - IJB-4-2

P. 61

Tan C, et al.

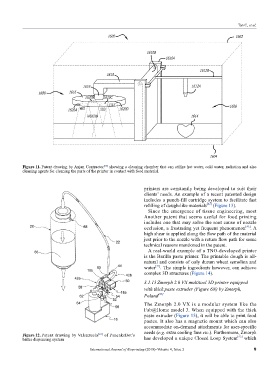

Figure 11. Patent drawing by Anjan Contractor showing a cleaning chamber that can utilize hot water, cold water, radiation and also

[39]

cleaning agents for cleaning the parts of the printer in contact with food material.

printers are constantly being developed to suit their

clients’ needs. An example of a recent patented design

includes a punch-fill cartridge system to facilitate fast

refilling of dough-like materials (Figure 13).

[42]

Since the emergence of tissue engineering, most

Another patent that seems useful for food printing

includes one that may solve the root cause of nozzle

occlusion, a frustrating yet frequent phenomenon [43] . A

high shear is applied along the flow path of the material

just prior to the nozzle with a return flow path for some

technical reasons mentioned in the patent.

A real-world example of a TNO-developed printer

is the Barilla pasta printer. The printable dough is all-

natural and consists of only durum wheat semolina and

water [41] . The simple ingredients however, can achieve

complex 3D structures (Figure 14).

3.1.13 Zmorph 2.0 VX multitool 3D printer equipped

with thick paste extruder (Figure 6N) by Zmorph,

Poland [45]

The Zmorph 2.0 VX is a modular system like the

Fab@Home model 3. When equipped with the thick

paste extruder (Figure 15), it will be able to print food

pastes. It also has a magnetic mount which can also

accommodate on-demand attachments for user-specific

needs (e.g. extra cooling fans etc.). Furthermore, Zmorph

Figure 12. Patent drawing by Valenzuela [40] of PancakeBot’s [45]

batter dispensing system has developed a unique Closed Loop System which

International Journal of Bioprinting (2018)–Volume 4, Issue 2 9