Page 82 - IJB-6-2

P. 82

3D printed fabric silicone composite

detailed changes in the Young’s modulus for every area between the fibers and yarns. The experimental

500 cycles are shown in Figure 6B. The percentage result evidently proved that the fabricated fabric

of decline in the Young’s modulus of the fabric silicone composite has a better durability in shape

silicone composite sample was 55% less than that recovery and mechanical properties after extension

of the fabric sample after 3000 cycles of testing. and recovery since the silicone matrix stabilizes

There was approximately 3% deformation that can the structure of the fabric which results in higher

be found in the fabric sample after 3000 cycles of elasticity. As a result, the pressure garment is able

testing while no deformation can be found for the to exert adequate pressure onto the skin of patients

fabric silicone composite. The images in Figure 6C during wear to provide better pressure therapy

and D show the deformation of the fabric after treatment. Apart from material fatigue, we have also

3000 cycles of testing. The reason of the fabric shown the tensile properties of the fabric silicone

deformation after tensile cycles could be explained composite and silicone samples using ASTM D638;

by the friction between the fiber and yarn in the Figure 6E. The fabricated samples are shown in

complex interlooping fabric structure. When the Figure 6F and G. The fabric reinforcement approach

tensile force is applied onto the fabric, the fabric is improved the strength of the 3D printed silicone.

extended and the loop is deformed in the vertical Our example shows the means of modifying the

direction. Once the force is released, the yarn and mechanical behavior of 3D printed soft material

fiber fail to recover to their original shapes due to using a fabric reinforcement method in a flexible

the high friction induced by the large contact surface way. Another advantage of the fabric reinforcement

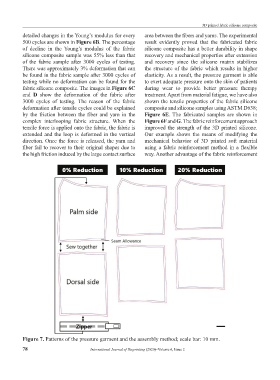

Figure 7. Patterns of the pressure garment and the assembly method; scale bar: 10 mm.

78 International Journal of Bioprinting (2020)–Volume 6, Issue 2