Page 75 - MSAM-3-1

P. 75

Materials Science in Additive Manufacturing Alumina platelets additive manufacturing

A B

C D

E F

G H

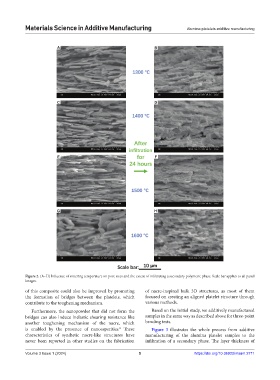

Figure 2. (A–H) Influence of sintering temperature on pore sizes and the extent of infiltrating a secondary polymeric phase. Scale bar applies to all panel

images.

of this composite could also be improved by promoting of nacre-inspired bulk 3D structures, as most of them

the formation of bridges between the platelets, which focused on creating an aligned platelet structure through

contribute to the toughening mechanism. various methods.

Furthermore, the nanopowder that did not form the Based on the initial study, we additively manufactured

bridges can also induce inelastic shearing resistance like samples in the same way as described above for three-point

another toughening mechanism of the nacre, which bending tests.

8

is enabled by the presence of nanoasperities. These Figure 3 illustrates the whole process from additive

characteristics of synthetic nacre-like structures have manufacturing of the alumina platelet samples to the

never been reported in other studies on the fabrication infiltration of a secondary phase. The layer thickness of

Volume 3 Issue 1 (2024) 5 https://doi.org/10.36922/msam.2711