Page 12 - MSAM-4-3

P. 12

Materials Science in Additive Manufacturing Ceramic vat photopolymerization

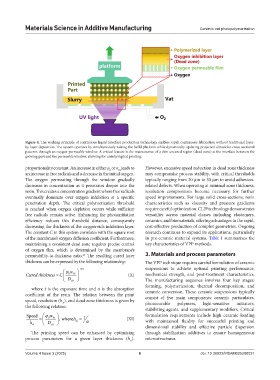

Figure 4. The working principle of continuous liquid interface production technology enables rapid, continuous fabrication without traditional layer-

by-layer deposition. The system operates by simultaneously raising the build platform while dynamically updating projected ultraviolet cross-sectional

patterns through an oxygen-permeable window. A critical feature is the maintenance of a thin uncured region (dead zone) at the interface between the

growing part and the permeable window, allowing for uninterrupted printing.

proportionality constant. An increase in either φ or α leads to However, excessive speed reduction in dead zone thickness

PI

0

an increase in free radicals and a decrease in the initial oxygen. may compromise process stability, with critical thresholds

The oxygen permeating through the window gradually typically ranging from 20 μm to 30 μm to avoid adhesion-

decreases in concentration as it penetrates deeper into the related defects. When operating at minimal zone thickness,

resin. This creates a concentration gradient where free radicals resolution compromises become necessary for further

eventually dominate over oxygen inhibition at a specific speed improvements. For large solid cross-sections, resin

penetration depth. The critical polymerization threshold characteristics such as viscosity and pressure gradients

is reached when oxygen depletion occurs while sufficient require careful optimization. CLIP technology demonstrates

free radicals remain active. Enhancing the photoinitiation versatility across material classes including elastomers,

efficiency reduces this threshold distance, consequently ceramics, and biomaterials, offering advantages in the rapid,

decreasing the thickness of the oxygen-rich inhibition layer. cost-effective production of complex geometries. Ongoing

The constant C in this system correlates with the square root research continues to expand its applications, particularly

of the membrane’s oxygen diffusion coefficient. Furthermore, in pre-ceramic material systems. Table 1 summarizes the

maintaining a consistent dead zone requires precise control key characteristics of VPP methods.

of oxygen flux, which is determined by the membrane’s

permeability-to-thickness ratio. The resulting cured layer 3. Materials and process parameters

23

thickness can be expressed by the following relationship: The VPP technique requires careful formulation of ceramic

05. suspensions to achieve optimal printing performance,

Cured thicknessC 0 PI (X) mechanical strength, and post-treatment characteristics.

D c0 The manufacturing sequence involves four key stages:

forming, polymerization, thermal decomposition, and

where t is the exposure time and α is the absorption ceramic conversion. These ceramic suspensions typically

coefficient of the resin. The relation between the print consist of five main components: ceramic particulates,

speed, resolution (h ), and dead zone thickness is given by photocurable polymers, light-sensitive initiators,

A

the following relation:

stabilizing agents, and supplementary modifiers. Critical

Speed PI , whereh 1 (XI) formulation requirements include high ceramic loading

0

h D A with maintained fluidity for successful printing and

A

c0

dimensional stability and effective particle dispersion

The printing speed can be enhanced by optimizing through stabilization additives to ensure homogeneous

process parameters for a given layer thickness (h ). microstructures.

A

Volume 4 Issue 3 (2025) 6 doi: 10.36922/MSAM025200031