Page 189 - IJB-10-1

P. 189

International Journal of Bioprinting Nanoclay biopolymer inks for 3D printing

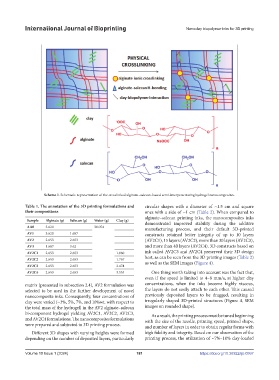

Scheme 1. Schematic representation of the crosslinked alginate–salecan-based semi-interpenetrating hydrogel nanocomposites.

Table 1. The annotation of the 3D printing formulations and circular shapes with a diameter of ~1.5 cm and square

their compositions ones with a side of ~1 cm (Table 2). When compared to

alginate–salecan printing inks, the nanocomposites inks

Sample Alginate (g) Salecan (g) Water (g) Clay (g) demonstrated improved stability during the additive

AA0 3.620 - 30.054 - manufacturing process, and their default 3D-printed

AV1 3.620 1.687 - constructs retained better integrity of up to 10 layers

AV2 2.653 2.653 - (AV2C1), 15 layers (AV2C2), more than 30 layers (AV2C3),

AV3 1.687 3.62 - and more than 40 layers (AV2C4). 3D constructs based on

AV2C1 2.653 2.653 1.060 ink called AV2C3 and AV2C4 preserved their 3D design

AV2C2 2.653 2.653 1.767 best, as can be seen from the 3D printing images (Table 2)

as well as the SEM images (Figure 4).

AV2C3 2.653 2.653 2.474

AV2C4 2.653 2.653 3.535 One thing worth taking into account was the fact that,

even if the speed is limited to 4–8 mm/s, at higher clay

matrix (presented in subsection 2.4), AV2 formulation was concentrations, when the inks become highly viscous,

selected to be used in the further development of novel the layers do not easily attach to each other. This caused

nanocomposite inks. Consequently, four concentrations of previously deposited layers to be dragged, resulting in

clay were varied (~3%, 5%, 7%, and 10%wt. with respect to irregularly shaped 3D-printed structures (Figure 4, SEM

the total mass of the hydrogel) in the AV2 alginate–salecan images on rounded shape).

bi-component hydrogel yielding AV2C1, AV2C2, AV2C3, As a result, the printing process must be tuned beginning

and AV2C4 formulations. The nanocomposites formulations with the size of the needle, printing speed, printed shape,

were prepared and subjected to 3D printing process. and number of layers in order to obtain regular forms with

Different 3D shapes with varying heights were formed high fidelity and integrity. Based on our observation of the

depending on the number of deposited layers, particularly printing process, the utilization of ~7%–10% clay-loaded

Volume 10 Issue 1 (2024) 181 https://doi.org/10.36922/ijb.0967