Page 372 - IJB-10-3

P. 372

International Journal of Bioprinting Multi-physical field control inkjet bioprinting

of a microdroplet determined the time it took to pass moving speed from 3 to 8 mm/s. When the system began to

through the temperature field, and the diameter of the operate, the reservoir of the feeding system was filled with

droplet determined the heat required for curing. After the bioink. A pressure controller (E19KP, OBKZN, China)

speed and diameter of the microdroplet were determined was used to provide negative pressure in the reservoir to

by adjusting the pressure field, the temperature field prevent the bioink from leaking out of the printhead. This

was adjusted to realize microdroplet formation. The study maintained the back pressure in the range from 0.9

temperature field included the feeding system, printhead, to 1.7 kPa. Next, the printhead controller sent a square

and air temperatures. The temperatures of the feeding driving wave that caused piezoelectric ceramics to control

system and printing head were adjusted using a water the pressure field in the printhead. Under the control of the

bath equipped with temperature control. The temperature pressure field, the microdroplets of appropriate diameter

of the cover and baseplate of the temperature controlled ultimately dropped with suitable velocity.

chamber were adjusted to control the air temperature. The

temperature field was used to control the temperature of the 2.6.2. Temperature field control system

microdroplets to complete the assembly process. Finally, the The second part of the printing system was the temperature

MFCPIB method was realized by controlling the pressure field control system, which controls the temperature of

and temperature fields to print 3D tissue-like structures. the entire printing process. The system mainly consists of

a temperature-controlled piezoelectric printhead system

2.6. Printing system of MFCPIB and temperature-controlled chamber. The system can

2.6.1. Pressure field control system be adjusted using cascade control. The temperature-

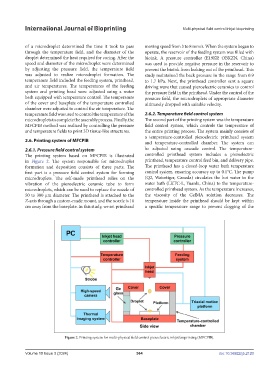

The printing system based on MFCPIB is illustrated controlled printhead system includes a piezoelectric

in Figure 2. The system responsible for microdroplet printhead, temperature control feed bin, and delivery pipe.

formation and deposition consists of three parts. The The printhead has a closed-loop water bath temperature

first part is a pressure field control system for forming control system, ensuring accuracy up to 0.1°C. The pump

microdroplets. The self-made printhead relies on the (Q2, Watertiger, Canada) circulates the hot water in the

vibration of the piezoelectric ceramic tube to form water bath (LKTC-L, Yuanlu, China) to the temperature-

microdroplets, which can be used to replace the nozzle of controlled printhead system. As the temperature increases,

50 to 300 μm diameter. The printhead is attached to the the viscosity of the GelMA solution decreases. The

Z-axis through a custom-made mount, and the nozzle is 10 temperature inside the printhead should be kept within

cm away from the baseplate. In this study, we set printhead a specific temperature range to prevent clogging of the

Figure 2. Printing system for multi-physical field control piezoelectric inkjet bioprinting (MFCPIB).

Volume 10 Issue 3 (2024) 364 doi: 10.36922/ijb.2120