Page 36 - IJB-4-1

P. 36

Jang T-S, et al.

stability. In this chapter, basic principle of popular laser- patterns of each layer can be achieved in the precisely

based 3D printing techniques for the hydrogels will be controlled optical scanning system with slightly larger

further discussed. focusing depth than the one-layer height [3,18] .

Generally, SLA 3D printing system has many advantages

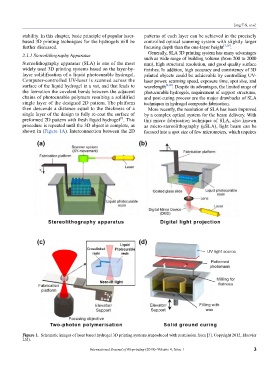

2.1.1 Stereolithography Apparatus such as wide range of building volume (from 200 to 2000

Stereolithography apparatus (SLA) is one of the most mm), high structural resolution, and good quality surface

widely used 3D printing systems based on the layer-by- finishes. In addition, high accuracy and consistency of 3D

layer solidification of a liquid photocurable hydrogel. printed objects could be achievable by controlling UV-

Computer-controlled UV-laser is scanned across the laser power, scanning speed, exposure time, spot size, and

surface of the liquid hydrogel in a vat, and that leads to wavelength [2,18] . Despite its advantages, the limited range of

the formation the covalent bonds between the adjacent photocurable hydrogels, requirement of support structures,

chains of photocurable polymers resulting a solidified and post-curing process are the major drawbacks of SLA

single layer of the designed 2D pattern. The platform techniques in hydrogel composite fabrication.

then descends a distance equal to the thickness of a More recently, the resolution of SLA has been improved

single layer of the design to fully re-coat the surface of by a complex optical system for the beam delivery. With

[3]

preformed 2D pattern with fresh liquid hydrogel . This this micro fabrication technique of SLA, also known

procedure is repeated until the 3D object is complete, as as micro-stereolithography (μSLA), light beam can be

shown in (Figure 1A). Interconnection between the 2D focused into a spot size of few micrometers, which requires

Figure 1. Schematic images of laser based hydrogel 3D printing systems.(reproduced with permission from [3]. Copyright 2012, Elsevier

Ltd).

International Journal of Bioprinting (2018)–Volume 4, Issue 1 3