Page 579 - IJB-10-4

P. 579

International Journal of Bioprinting 3D-printing silicone patient-specific soft-tissue expander

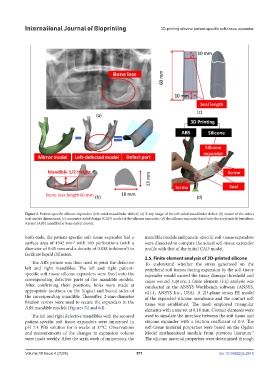

Figure 5. Patient-specific silicone expanders (left-sided mandibular defect): (a) X-ray image of the left-sided mandibular defect; (b) model of the defect

part and its dimensions; (c) computer-aided design (CAD) model of the silicone expander; (d) the silicone expander fixed onto the acrylonitrile butadiene

styrene (ABS) mandibular bone defect model.

both ends, the patient-specific soft-tissue expander had a mandible models and patient-specific soft-tissue expanders

3

surface area of 4342 mm with 160 perforations (with a were dissected to compare the actual soft-tissue expander

2

diameter of 0.65 mm and a density of 0.038 hole/mm ) to profile with that of the initial CAD model.

facilitate liquid diffusion.

2.5. Finite element analysis of 3D-printed silicone

The ABS printer was then used to print the defective To understand whether the stress generated on the

left and right mandibles. The left and right patient- peripheral soft tissues during expansion by the soft-tissue

specific soft-tissue silicone expanders were fixed onto the expander would exceed the tissue damage threshold and

corresponding defective parts of the mandible models. cause wound rupture, a finite element (FE) analysis was

After confirming their positions, holes were made at conducted in the ANSYS Workbench software (ANSYS,

appropriate locations on the lingual and buccal sides of v21.1, ANSYS Inc., USA). A 2D-plane strain FE model

the corresponding mandible. Thereafter, 2-mm-diameter of the expanded silicone membrane and the contact soft

fixation screws were used to secure the expanders to the tissue was established. The mesh employed triangular

ABS mandible models (Figures 5d and 6d). elements with a size set at 0.18 mm. Contact elements were

The left and right defective mandibles with the secured used to simulate the interface between the soft tissue and

patient-specific soft tissue expanders were immersed in silicone expander with a friction coefficient of 0.9. The

pH 7.4 PBS solution for 6 weeks at 37°C. Observations soft-tissue material properties were based on the Ogden

and measurements of the changes in expansion volume Model mathematical module from previous literature.

7

were made weekly. After the sixth week of immersion, the The silicone material properties were determined through

Volume 10 Issue 4 (2024) 571 doi: 10.36922/ijb.2918