Page 11 - IJB-6-2

P. 11

Agarwala

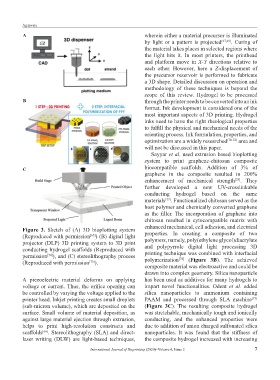

A wherein either a material precursor is illuminated

by light or a pattern is projected [67,69] . Curing of

the material takes places in selected regions where

the light hits it. In most printers, the printhead

and platform move in X-Y directions relative to

each other. However, here a Z-displacement of

the precursor reservoir is performed to fabricate

a 3D shape. Detailed discussion on operation and

methodology of these techniques is beyond the

scope of this review. Hydrogel to be processed

B through the printer needs to be converted into an ink

format. Ink development is considered one of the

most important aspects of 3D printing. Hydrogel

inks need to have the right rheological properties

to fulfill the physical and mechanical needs of the

orienting process. Ink formulation, properties, and

optimization are a widely researched [70-72] area and

will not be discussed in this paper.

Sayyar et al. used extrusion based bioplotting

system to print graphene-chitosan composite

C biocompatible scaffolds. Addition of 3% of

graphene in the composite resulted in 200%

enhancement of mechanical strength . They

[28]

further developed a new UV-crosslinkable

conducting hydrogel based on the same

materials . Functionalized chitosan served as the

[73]

host polymer and chemically converted graphene

as the filler. The incorporation of graphene into

chitosan resulted in cytocompatible matrix with

Figure 3. Sketch of (A) 3D bioplotting system enhanced mechanical, cell adhesion, and electrical

(Reproduced with permission ) (B) digital light properties. In creating a composite of two

[65]

projector (DLP) 3D printing system to 3D print polymers, namely, poly(ethylene glycol)diacrylate

conducting hydrogel scaffolds (Reproduced with and polypyrrole digital light processing 3D

permission ), and (C) stereolithography process printing technique was combined with interfacial

[74]

[74]

(Reproduced with permission ). polymerization (Figure 3B). The achieved

[75]

composite material was electroactive and could be

drawn into complex geometry. Silica nanoparticle

A piezoelectric material deforms on applying has been used as additives for many hydrogels to

voltage or current. Thus, the orifice opening can impart novel functionalities. Odent et al. added

be controlled by varying the voltage applied to the silica nanoparticles to ammonium containing

printer head. Inkjet printing creates small droplets PAAM and processed through SLA machine

[75]

(sub-micron volume), which are deposited on the (Figure 3C). The resulting composite hydrogel

surface. Small volume of material deposition, as was stretchable, mechanically tough and ionically

against large material ejection through extrusion, conducting, and the enhanced properties were

helps to print high-resolution constructs and due to addition of anion charged sulfonated silica

scaffolds . Stereolithography (SLA) and direct- nanoparticles. It was found that the stiffness of

[66]

laser writing (DLW) are light-based techniques, the composite hydrogel increased with increasing

International Journal of Bioprinting (2020)–Volume 6, Issue 2 7