Page 38 - MSAM-3-2

P. 38

Materials Science in Additive Manufacturing LPBF of Ti-Al-graded multi-materials

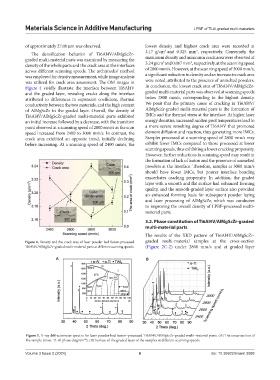

of approximately 27.00 μm was observed. lowest density and highest crack area were recorded at

2

3

The densification behavior of Ti6Al4V/AlMgScZr- 3.17 g/cm and 0.325 mm , respectively. Conversely, the

graded multi-material parts was examined by measuring the maximum density and minimum crack area were observed at

2

3

density of the whole parts and the crack area at the interfaces 3.24 g/cm and 0.067 mm , respectively, at the scanning speed

across different scanning speeds. The archimedes’ method of 2800 mm/s. However, at the scanning speed of 3000 mm/s,

was employed for density measurement, while image analysis a significant reduction in density and an increase in crack area

was utilized for crack area assessment. The OM images in were noted, attributed to the presence of unmelted powders.

Figure 4 vividly illustrate the interface between Ti6Al4V In conclusion, the lowest crack area of Ti6Al4V/AlMgScZr-

and the graded layer, revealing cracks along the interface graded multi-material parts was observed at scanning speeds

attributed to differences in expansion coefficient, thermal below 2800 mm/s, corresponding to the highest density.

conductivity between the two materials, and the high content We posit that the primary cause of cracking in Ti6Al4V/

of AlMgScZr in the graded layer. Overall, the density of AlMgScZr-graded multi-material parts is the formation of

Ti6Al4V/AlMgScZr-graded multi-material parts exhibited IMCs and the thermal stress at the interface. At higher laser

an initial increase followed by a decrease, with the transition energy densities, increased molten pool temperatures lead to

point observed at a scanning speed of 2800 mm/s as the scan a more severe remelting degree of Ti6Al4V that promoted

speed increased from 2400 to 3000 mm/s. In contrast, the element diffusion and reaction, thus generating more IMCs.

crack area exhibited an opposite trend, initially declining Samples processed at a scanning speed of 2800 mm/s may

before increasing. At a scanning speed of 2400 mm/s, the exhibit fewer IMCs compared to those processed at lower

scanning speeds, thus exhibiting a lower cracking propensity.

However, further reductions in scanning speed may result in

the formation of lack of fusion and the presence of unmelted

powders at the interface. Therefore, samples at 3000 mm/s

should have fewer IMCs, but poorer interface bonding

exacerbates cracking propensity. In addition, the graded

layer with a smooth and flat surface had enhanced forming

quality, and the smooth-graded layer surface also provided

an enhanced forming basis for subsequent powder laying

and laser processing of AlMgScZr, which was conducive

to improving the overall density of LPBF-processed multi-

material parts.

3.2. Phase constitution of Ti6Al4V/AlMgScZr-graded

multi-material parts

The results of the XRD pattern of Ti6Al4V/AlMgScZr-

Figure 4. Density and the crack area of laser powder bed fusion-processed graded multi-material samples at the cross-section

Ti6Al4V/AlMgScZr-graded multi-material parts at different scanning speeds. (Figure 2C-2) under 2800 mm/s and at graded layer

A B

Figure 5. X-ray diffractometer spectra for laser powder bed fusion-processed Ti6Al4V/AlMgScZr-graded multi-material parts. (A) The cross-section of

the sample (Inset: Ti-Al phase diagram ). (B) Surface of the graded layer of the samples at different scanning speeds.

28

Volume 3 Issue 2 (2024) 6 doi: 10.36922/msam.3088