Page 127 - MSAM-4-2

P. 127

Materials Science in Additive Manufacturing Mouthguards: Disinfection versus properties changes

resolution of 4.0 cm , using 24 accumulations and a The resulting multi-material configurations are depicted

-1

constant applied force across all acquisitions. in Figure 2. The 3D-printed parts exhibit a parallelepipedal

geometry with dimensions of 60 × 10 × 2 mm3. The printed

2.3. Fabrication and disinfection procedures specimens demonstrated dimensional consistency, with a

2.3.1. 3D printing standard deviation of approximately 0.1 mm.

All testing specimens were prepared using FFF technology 2.3.2. Disinfection of 3D-printed components

with a FlashForge Creator3 3D printer (Filament2Print,

Spain), equipped with a dual extruder, each fitted with a Proper cleaning and disinfection of mouthguards are

0.4 mm diameter nozzle. Specimens were printed with a essential for the health and well-being of athletes.

layer height of 0.1 mm and a printing speed of 40 mm/s. Accordingly, two disinfection methods were tested: a

A 100% line infill with a -45°/45° orientation was applied to chemical approach using commercially available cleaning

all parts to ensure uniform stress distribution and reduced tablets (Polident) and a physical approach using UVC

anisotropic mechanical behavior. 11,17 irradiation (λ = 254 nm; Germix SM-504B, Amazon EU,

Luxembourg).

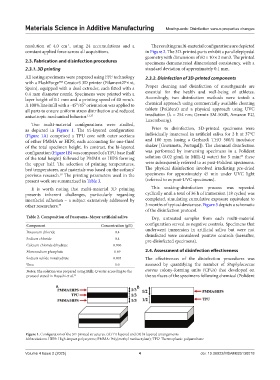

Two multi-material configurations were studied,

as depicted in Figure 1. The tri-layered configuration Prior to disinfection, 3D-printed specimens were

(Figure 1A) comprised a TPU core with outer sections individually immersed in artificial saliva for 2 h at 37℃

of either PMMA or HIPS, each accounting for one-third and 100 rpm (using a Gerhardt THO 500/1 incubator

of the total specimen height. In contrast, the bi-layered shaker [Gravimeta, Portugal]). The chemical disinfection

configuration (Figure 1B) was composed of a TPU base (half was performed by immersing specimens in a Polident

23

of the total height) followed by PMMA or HIPS forming solution (0.02 g/mL in Milli-Q water) for 5 min; these

the upper half. The selection of printing temperatures, were subsequently referred to as post-Polident specimens.

bed temperatures, and materials was based on the authors’ The physical disinfection involved irradiating pre-dried

previous research. The printing parameters used in the specimens for approximately 45 min under UVC light

19

present work are summarized in Table 3. (referred to as post-UVC specimens).

It is worth noting that multi-material 3D printing This soaking-disinfection process was repeated

presents inherent challenges, particularly regarding cyclically until a total of 36 h of immersion (18 cycles) was

interfacial adhesion – a subject extensively addressed by completed, simulating cumulative exposure equivalent to

other researchers. 33 3 months of typical device use. Figure 3 depicts a schematic

of the disinfection protocol.

Table 2. Composition of Fusayama–Meyer artificial saliva Dry, untreated samples from each multi-material

Component Concentration (g/L) configuration served as negative controls. Specimens that

underwent immersion in artificial saliva but were not

Potassium chloride 0.4 disinfected were considered positive controls (hereafter,

Sodium chloride 0.4 pre-disinfected specimens).

Calcium chloride dihydrate 0.906

Monosodium phosphate 0.69 2.4. Assessment of disinfection effectiveness

Sodium sulfide nonahydrate 0.005 The effectiveness of the disinfection procedures was

Urea 1.0 assessed by quantifying the number of Staphylococcus

Notes: The solution was prepared using Milli-Q water according to the aureus colony-forming units (CFUs) that developed on

protocol stated in Hayashi et al. 23 the surfaces of the specimens following chemical (Polident

A B

Figure 1. Configuration of the 3D-printed structures. (A) Tri-layered and (B) bi-layered arrangements

Abbreviations: HIPS: High-impact polystyrene; PMMA: Poly(methyl methacrylate); TPU: Thermoplastic polyurethane

Volume 4 Issue 2 (2025) 4 doi: 10.36922/MSAM025130018