Page 194 - AJWEP-v22i3

P. 194

Vasylkovska, et al.

“Rutan” basil (Ocimum basilicum), developed by the the range of 20 – 24°C, with a relative humidity of

“Mayak” Research Station of the Institute of Vegetable 60 – 70%.

and Melon Growing of the National Academy of

Agricultural Sciences, Ukraine. The vegetation period To enhance the efficiency of growing vegetable and

for this variety ranges from 60 to 66 days. berry crops, the Central Ukrainian National Technical

The main parameters of the study included: University developed a pilot portable hydroponic NFT

7,21

(i) A standard hydroponic nutrient solution formulated unit incorporating phytomatrix. This unit operates

for leafy crops, containing micro- and macroelements on the NFT principle and features a vertical column-

within the recommended concentration range shaped structure that ensures compactness and allows

for basil. To enhance the nutrient solution, the a fixed number of plants to be grown within a limited

20

effective microorganisms-5 (EM-5) preparation space (Figures 1 and 2A).

was incorporated. This preparation contains As illustrated in Figure 1, the hydroponic column

beneficial microorganisms known to stimulate root (number 8) is a pipe that contains a nutrient solution

system activity, improve physiological processes, supply pipe (number 7), which is fed from a reservoir

and increase plant yields. 16 (number 9) to the top of the column through a pumping

(ii) Phytomatrices with red and blue LED emitting system and water pump (number 11). Inside the reservoir,

elements in a ratio of 4:1 were used for lighting. 21,22 a sensor (number 10) monitors the minimum nutrient

(iii) The temperature regime was maintained within solution level to maintain proper operation. At the upper

part of the hydroponic column (number 8), there is an

air valve (number 1), a nutrient solution distribution

unit (number 2), and a phytomatrix attachment unit

(number 3) equipped with radiating elements. Below

this is the nutrient solution supply unit (number 4), to

which phytomatrix components (number 5) are attached

and extended downward. Equally spaced around the

A B

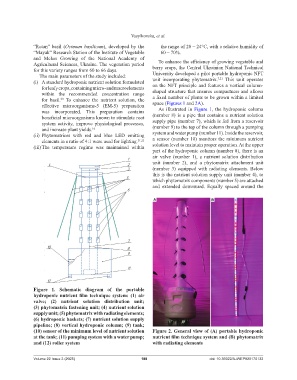

Figure 1. Schematic diagram of the portable

hydroponic nutrient film technique system: (1) air

valve; (2) nutrient solution distribution unit;

(3) phytomatrix fastening unit; (4) nutrient solution

supply unit; (5) phytomatrix with radiating elements;

(6) hydroponic baskets; (7) nutrient solution supply

pipeline; (8) vertical hydroponic column; (9) tank;

(10) sensor of the minimum level of nutrient solution Figure 2. General view of (A) portable hydroponic

at the tank; (11) pumping system with a water pump; nutrient film technique system and (B) phytomatrix

and (12) roller system with radiating elements

Volume 22 Issue 3 (2025) 188 doi: 10.36922/AJWEP025170132