Page 25 - ESAM-1-4

P. 25

Engineering Science in

Additive Manufacturing Machine learning for biomedical metal AM

A B

C

D E

11

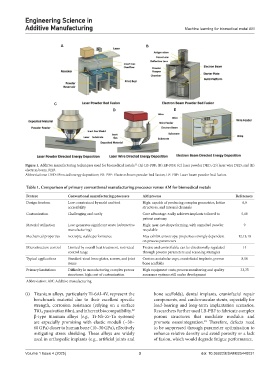

Figure 1. Additive manufacturing techniques used for biomedical metals. (A) LB-PBF; (B) EB-PBF; (C) laser powder DED; (D) laser wire DED; and (E)

electron beam DED.

Abbreviations: DED: Directed energy deposition; EB-PBF: Electron beam powder bed fusion; LB-PBF: Laser beam powder bed fusion.

Table 1. Comparison of primary conventional manufacturing processes versus AM for biomedical metals

Feature Conventional manufacturing processes AM process References

Design freedom Low: constrained by mold and tool High: capable of producing complex geometries, lattice 6,9

accessibility structures, and internal channels

Customization Challenging and costly Core advantage: easily achieves implants tailored to 5,10

patient anatomy

Material utilization Low: generates significant waste (subtractive High: near-net-shape forming, with unmelted powder 9

manufacturing) recyclable

Mechanical properties Isotropic, stable performance May exhibit anisotropy; properties strongly dependent 12,13,18

on process parameters

Microstructure control Limited by overall heat treatment, restricted Precise and controllable; can be directionally regulated 14

control range through process parameters and scanning strategies

Typical applications Standard-sized bone plates, screws, and joint Custom acetabular cups, craniofacial implants, porous 8,10

stems bone scaffolds

Primary limitations Difficulty in manufacturing complex porous High equipment costs; process monitoring and quality 33,35

structures; high cost of customization assurance systems still under development

Abbreviation: AM: Additive manufacturing.

(i) Titanium alloys, particularly Ti-6Al-4V, represent the bone scaffolds), dental implants, craniofacial repair

benchmark material due to their excellent specific components, and cardiovascular stents, especially for

strength, corrosion resistance (relying on a surface load-bearing and long-term implantation scenarios.

TiO₂ passivation film), and inherent biocompatibility. Researchers further used LB-PBF to fabricate complex

22

β-type titanium alloys (e.g., Ti-Nb-Zr-Ta systems) porous structures that modulate modulus and

are especially promising with elastic moduli (~30– promote osseointegration. Therefore, defects need

23

60 GPa) closer to human bone (10–30 GPa), effectively to be suppressed through parameter optimization to

mitigating stress shielding. These alloys are widely enhance relative density and avoid porosity or a lack

used in orthopedic implants (e.g., artificial joints and of fusion, which would degrade fatigue performance.

Volume 1 Issue 4 (2025) 3 doi: 10.36922/ESAM025440031