Page 54 - IJB-10-3

P. 54

International Journal of Bioprinting 3D-printed biodegradable metals for bone regeneration

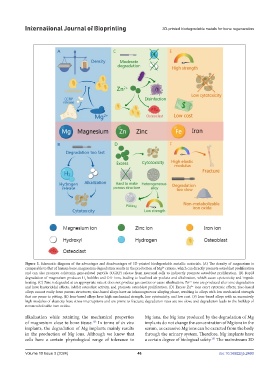

Figure 3. Schematic diagram of the advantages and disadvantages of 3D-printed biodegradable metallic materials. (A) The density of magnesium is

2+

comparable to that of human bone; magnesium degradation results in the production of Mg cations, which can directly promote osteoblast proliferation

and can also promote calcitonin gene-related peptide (CGRP) release from neuronal cells to indirectly promote osteoblast proliferation. (B) Rapid

-

degradation of magnesium produces H bubbles and OH ions, leading to localized air pockets and alkalization, which cause cytotoxicity and impede

2

2+

healing. (C) Zinc is degraded at an appropriate rate; it does not produce gas cavities or cause alkalization; Zn ions are produced after zinc degradation

2+

and have bactericidal effects, inhibit osteoclast activity, and promote osteoblast proliferation. (D) Excess Zn ions exert cytotoxic effects; zinc-based

alloys cannot easily form porous structures; zinc-based alloys have an inhomogeneous alloying phase, resulting in alloys with low mechanical strength

that are prone to pitting. (E) Iron-based alloys have high mechanical strength, low cytotoxicity, and low cost. (F) Iron-based alloys with an excessively

high modulus of elasticity have stress interruptions and are prone to fracture; degradation rates are too slow; and degradation leads to the buildup of

nonmetabolizable iron oxides.

alkalization while retaining the mechanical properties Mg ions, the Mg ions produced by the degradation of Mg

of magnesium close to bone tissue. In terms of in vivo implants do not change the concentration of Mg ions in the

123

implants, the degradation of Mg implants mainly results serum, as excessive Mg ions can be excreted from the body

in the production of Mg ions. Although we know that through the urinary system. Therefore, Mg implants have

cells have a certain physiological range of tolerance to a certain degree of biological safety. The mainstream 3D

131

Volume 10 Issue 3 (2024) 46 doi: 10.36922/ijb.2460