Page 138 - IJB-10-4

P. 138

International Journal of Bioprinting 3D printing innovations against infection

3D-printed scaffold manufacturing technology has led copper, zinc oxide, titanium dioxide, or copper oxide) can

to tremendous advances in the treatment of orthopedic be continuously released from the scaffold equipped with

infection, exhibiting increased diversity and widespread antibacterial activity to address drug resistance (Figure 4B).

101

application. 96,97 These antimicrobial modifications (iii) Coatings on 3D-printed scaffolds: bioactive metal

predominantly include the following methods: (i) Drug ions and antimicrobial coating 3D-printed scaffolds can

loading into 3D-printed scaffolds : 3D printing is used to simultaneously fight against bone infection and treat

98

fabricate implants incorporated with antimicrobial agents osteomyelitis by improving the microenvironment of the

to mitigate infection risks, a promising avenue for treating infected bone defect, rapidly inhibiting the reproduction

99

implant infections (Figure 4A). (ii) Incorporating of pathogenic bacteria, and preventing the inflammatory

100

antimicrobial nanoparticles into 3D-printed scaffolds: response in the early stage of infection (Figure 4C).

102

antimicrobial nanoparticles (e.g., silver, gold, selenium, (iv) Cell-based therapies: the 3D porous scaffold can be

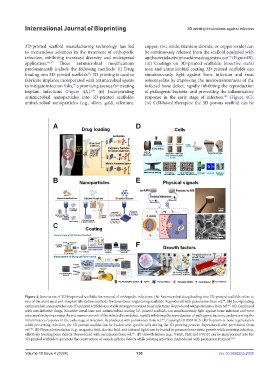

Figure 4. Innovation of 3D-bioprinted scaffolds for removal of orthopedic infections. (A) Antimicrobial drug loading into 3D-printed scaffolds refers to

one of the most used and simplest fabrication methods for bone tissue engineering scaffolds. Reproduced with permission from ref. . (B) Incorporating

98

antimicrobial nanoparticles into 3D-printed scaffolds is a viable strategy to combat bone infections. Reproduced with permission from ref. . (C) Combined

101

with anti-infective drugs, bioactive metal ions and antimicrobial coating 3D-printed scaffolds can simultaneously fight against bone infection and treat

osteomyelitis by improving the microenvironment of the infected bone defect, rapidly inhibiting the reproduction of pathogenic bacteria, and preventing the

inflammatory response in the early stage of infection. Reproduced with permission from ref. . Copyright © 2020 ACS. (D) To promote bone regeneration

102

while preventing infection, the 3D porous scaffold can be loaded with specific cells during the 3D printing process. Reproduced with permission from

ref. . (E) Physical stimulation (e.g., magnetic field, electric field, and infrared light) can be loaded to promote bone tissue growth while resisting infection,

103

effectively treating bone defects. Reproduced with permission from ref. . (F) Growth factors (e.g., VEGF, FGF, and PVDF) can be incorporated into the

104

3D-printed scaffolds to promote the construction of vessels in bone defects while resisting infection. Reproduced with permission from ref. .

100

Volume 10 Issue 4 (2024) 130 doi: 10.36922/ijb.2338