Page 133 - IJB-10-4

P. 133

International Journal of Bioprinting 3D printing innovations against infection

of 3D-printed anti-infection materials within the medical materials and shapes. The fundamental concept involves

domain, along with the application of novel materials. the meticulous printing of antibiotics, nanoparticles, cells,

and other biomaterial structures onto substrates, utilizing

2. Research progress in 3D printing specialized printing systems tailored to the requirements

technology for anti-infection materials of bionic morphology, organismal function, and cellular

microenvironment. Fused deposition modeling (FDM,

28

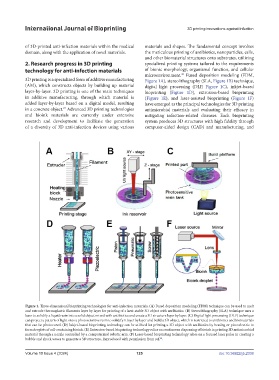

3D printing is a specialized form of additive manufacturing Figure 1A), stereolithography (SLA, Figure 1B) technique,

(AM), which constructs objects by building up material digital light processing (DLP, Figure 1C), inkjet-based

layer-by-layer. 3D printing is one of the main techniques bioprinting (Figure 1D), extrusion-based bioprinting

in additive manufacturing, through which material is (Figure 1E), and laser-assisted bioprinting (Figure 1F)

added layer-by-layer based on a digital model, resulting have emerged as the principal technologies for 3D printing

in a concrete object. Advanced 3D printing technologies antimicrobial materials and evaluating their efficacy in

27

and bioink materials are currently under extensive mitigating infection-related diseases. Each bioprinting

research and development to facilitate the generation system produces 3D structures with high fidelity through

of a diversity of 3D anti-infection devices using various computer-aided design (CAD) and manufacturing, and

Figure 1. Three-dimensional bioprinting technologies for anti-infection materials. (A) Fused deposition modeling (FDM) technique can be used to melt

and extrude thermoplastic filaments layer by layer for printing of a heat-stable 3D object with antibiotics. (B) Stereolithography (SLA) technique uses a

laser to solidify a liquid resin into a solid object mixed with antibiotics and create a 3D structure layer by layer. (C) Digital light processing (DLP) technique

can project a pattern of light onto a photosensitive resin to solidify it layer by layer and build a 3D object, which is restricted to antibiotics and biomaterials

that can be photocured. (D) Inkjet-based bioprinting technology can be utilized for printing a 3D object with antibiotics by heating or piezoelectric to

form droplets of cell-containing bioink. (E) Extrusion-based bioprinting technology relies on continuous dispensing of bioink in printing 3D antimicrobial

material through a nozzle controlled by a computerized robotic arm. (F) Laser-based bioprinting technology relies on a focused laser pulse in creating a

bubble and shock waves to generate a 3D structure. Reproduced with permission from ref. .

28

Volume 10 Issue 4 (2024) 125 doi: 10.36922/ijb.2338