Page 180 - IJB-10-5

P. 180

International Journal of Bioprinting Control nutrients to manipulate fungal growth

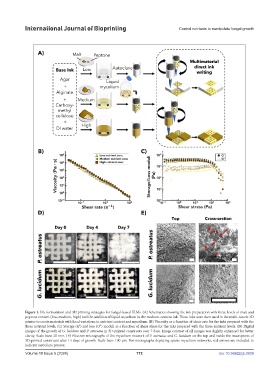

Figure 1. Ink formulation and 3D printing strategies for fungal-based ELMs. (A) Schematics showing the ink preparation with three levels of malt and

peptone content (low, medium, high) and the addition of liquid mycelium in the medium-content ink. These inks were then used in the multi-nozzle 3D

printer to create materials with local variations in nutrient content and mycelium. (B) Viscosity as a function of shear rate for the inks prepared with the

three nutrient levels. (C) Storage (G’) and loss (G’’) moduli as a function of shear stress for the inks prepared with the three nutrient levels. (D) Digital

images of the growth of G. lucidum and P. ostreatus in 3D-printed constructs over 7 days. Image contrast of all images was slightly enhanced for better

clarity. Scale bars: 20 mm. (E) Electron micrographs of the mycelium network of P. ostreatus and G. lucidum on the top and inside the macropores of

3D-printed constructs after 14 days of growth. Scale bars: 100 μm. For micrographs depicting sparse mycelium networks, red arrows are included to

indicate mycelium present.

Volume 10 Issue 5 (2024) 172 doi: 10.36922/ijb.3939