Page 376 - IJB-10-5

P. 376

International Journal of Bioprinting Tunable anisotropic gyroid bioscaffolds

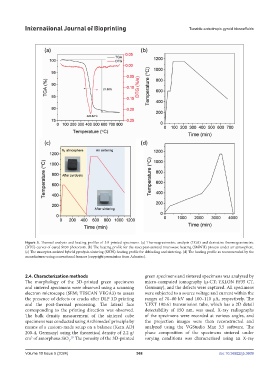

Figure 3. Thermal analysis and heating profiles of 3D printed specimens. (a) Thermogravimetric analysis (TGA) and derivative thermogravimetric

(DTG) curves of cured S130 photoresin. (b) The heating profile for the susceptor-assisted microwave heating (SMWH) process under air atmosphere.

(c) The susceptor-assisted hybrid pyrolysis-sintering (SHPS) heating profile for debinding and sintering. (d) The heating profile as recommended by the

manufacturer using conventional furnace (copyright permission from Admatec).

2.4. Characterization methods green specimens and sintered specimens was analyzed by

The morphology of the 3D-printed green specimens micro-computed tomography (µ-CT; YXLON FF35 CT,

and sintered specimens were observed using a scanning Germany), and the defects were captured. All specimens

electron microscope (SEM; TESCAN VEGA3) to assess were subjected to a source voltage and current within the

the presence of defects or cracks after DLP 3D printing ranges of 70–80 kV and 100–110 µA, respectively. The

and the post-thermal processing. The lateral face Y.FXT 190.61 transmission tube, which has a 2D detail

corresponding to the printing direction was observed. detectability of 150 nm, was used. X-ray radiographs

The bulk density measurement of the sintered cube of the specimens were recorded at various angles, and

specimens was conducted using Archimedes’ principle by the projection images were then reconstructed and

means of a custom-made setup on a balance (Kern ADJ analyzed using the VGStudio Max 3.5 software. The

200-4, Germany) using the theoretical density of 2.2 g/ phase composition of the specimens sintered under

cm of amorphous SiO . The porosity of the 3D-printed varying conditions was characterized using an X-ray

29

3

2

Volume 10 Issue 5 (2024) 368 doi: 10.36922/ijb.3609