Page 50 - IJB-7-2

P. 50

Investigating the Influence of Architecture and Material Composition of 3D Printed Anatomical Design Scaffolds for Large Bone Defects

A A B

C D

B

E F

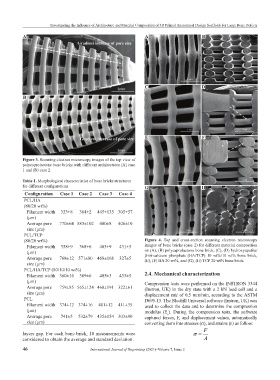

Figure 3. Scanning electron microscopy images of the top view of

polycaprolactone bone bricks with different architectures (A) case

1 and (Β) case 2.

Table 1. Morphological characteristics of bone bricks structures

for different configurations G H

Configuration Case 1 Case 2 Case 3 Case 4

PCL/HA

(80/20 wt%)

Filament width 353±8 364±2 445±135 305±57

(μm)

Average pore 770±64 583±102 400±8 406±10

size (μm)

PCL/TCP

(80/20 wt%) Figure 4. Top and cross-section scanning electron microscopy

Filament width 358±9 368±6 403±9 431±5 images of bone bricks (case 2) for different material composition

(μm) on (A), (B) polycaprolactone bone brick, (C), (D) hydroxyapatite/

Average pore 768±12 571±80 468±168 327±5 β-tri-calcium phosphate (HA/TCP) 10 wt%/10 wt% bone brick,

(E), (F) HA 20 wt%, and (G), (H) TCP 20 wt% bone brick.

size (μm)

PCL/HA/TCP (80/10/10 wt%)

Filament width 360±16 369±6 405±3 433±5 2.4. Mechanical characterization

(μm) Compression tests were performed on the INSTRON 3344

Average pore 759±85 565±124 460±191 322±61 (Instron, UK) in the dry state with a 2 kN load cell and a

size (μm) displacement rate of 0.5 mm/min, according to the ASTM

PCL D695-15. The Bluehill Universal software (Instron, UK) was

Filament width 374±12 374±16 401±12 411±35 used to collect the data and to determine the compression

(μm) modulus (E ). During the compression tests, the software

c

Average pore 741±5 532±79 435±154 303±90 captured forces, F, and displacement values, automatically

size (μm) converting them into stresses (σ), and strains (ε) as follow:

F

layers gap. For each bone brick, 10 measurements were =

considered to obtain the average and standard deviation. A

46 International Journal of Bioprinting (2021)–Volume 7, Issue 2