Page 413 - IJB-9-3

P. 413

International Journal of Bioprinting Cellular metamaterial flexure joints

A

B

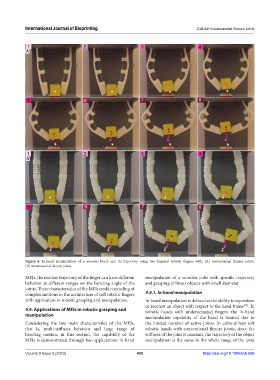

Figure 4. In-hand manipulation of a wooden block and its trajectory using two-fingered robotic fingers with: (A) conventional flexure joints;

(B) metamaterial flexure joints.

MFJs, the motion trajectory of the finger can have different manipulation of a wooden cube with specific trajectory

behavior at different ranges on the bending angle of the and grasping of linear objects with small diameter.

joints. These characteristics of the MFJs enable encoding of

complex motions in the architecture of soft robotic fingers 4.4.1. In-hand manipulation

with application in robotic grasping and manipulation. In-hand manipulation is defined as the ability to reposition

or reorient an object with respect to the hand frame . In

[22]

4.4. Applications of MFJs in robotic grasping and robotic hands with underactuated fingers, the in-hand

manipulation manipulation capability of the hand is limited due to

Considering the two main characteristics of the MFJs, the limited number of active joints. In cable-driven soft

that is, multi-stiffness behavior and large range of robotic hands with conventional flexure joints, since the

bending motion, in this section, the capability of the stiffness of the joint is constant, the trajectory of the object

MFJs is demonstrated through two applications: in-hand manipulation is the same in the whole range of the joint

Volume 9 Issue 3 (2023) 405 https://doi.org/10.18063/ijb.696