Page 99 - IJB-9-4

P. 99

International Journal of Bioprinting 3D-Printed liver model

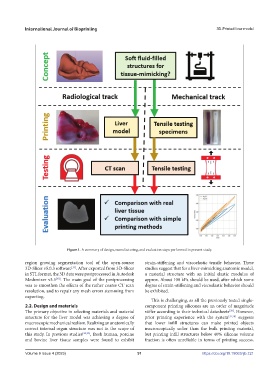

Figure 1. A summary of design, manufacturing, and evaluation steps performed in present study.

region growing segmentation tool of the open-source strain-stiffening and viscoelastic tensile behavior. These

[39]

3D-Slicer v5.0.3 software . After exported from 3D-Slicer studies suggest that for a liver-mimicking anatomic model,

in STL format, the 3D data were postprocessed in Autodesk a material structure with an initial elastic modulus of

[40]

Meshmixer v3.5 . The main goal of the postprocessing approx. About 100 kPa should be used, after which some

was to smoothen the effects of the rather coarse CT scan degree of strain-stiffening and viscoelastic behavior should

resolution, and to repair any mesh errors stemming from be exhibited.

exporting.

This is challenging, as all the previously tested single-

2.2. Design and materials component printing silicones are an order of magnitude

[38]

The primary objective in selecting materials and material stiffer according to their technical datasheets . However,

structure for the liver model was achieving a degree of prior printing experience with the system [37,38] suggests

macroscopic mechanical realism. Realizing an anatomically that lower infill structures can make printed objects

correct internal organ structure was not in the scope of macroscopically softer than the bulk printing material,

this study. In previous studies [36,35] , fresh human, porcine but printing infill structures below 40% silicone volume

and bovine liver tissue samples were found to exhibit fraction is often unreliable in terms of printing success.

Volume 9 Issue 4 (2023) 91 https://doi.org/10.18063/ijb.721