Page 57 - MSAM-1-4

P. 57

Materials Science in Additive Manufacturing LPBF of Mg and its bio-applications

A B C

D E

Figure 4. (A-E) SEM images of SLMed ZK60 alloy surface morphologies at different energy density .

[44]

A B C

D E F

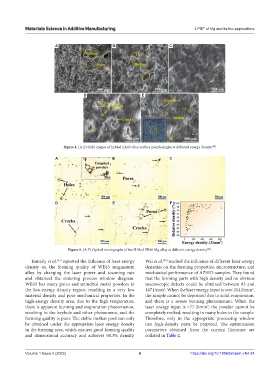

Figure 5. (A-F) Optical micrographs of the SLMed ZK60 Mg alloy at different energy density .

[44]

Esmaily et al. reported the influence of laser energy Wei et al. studied the influence of different laser energy

[46]

[45]

density on the forming quality of WE43 magnesium densities on the forming properties, microstructure, and

alloy by changing the laser power and scanning rate mechanical performance of AZ91D samples. They found

and obtained the sintering process window diagram. that the forming parts with high density and no obvious

WE43 has many pores and unmelted metal powders in macroscopic defects could be obtained between 83 and

the low-energy density region, resulting in a very low 167 J/mm . When the laser energy input is over 214 J/mm ,

3

3

material density and poor mechanical properties. In the the sample cannot be deposited due to solid evaporation,

high-energy density area, due to the high temperature, and there is a severe burning phenomenon. When the

3

there is apparent burning and evaporation phenomenon, laser energy input is <77 J/mm , the powder cannot be

resulting in the keyhole and other phenomena, and the completely melted, resulting in many holes in the sample.

forming quality is poor. The stable molten pool can only Therefore, only in the appropriate processing window

be obtained under the appropriate laser energy density can high-density parts be prepared. The optimization

in the forming area, which ensures good forming quality parameters obtained from the current literature are

and dimensional accuracy and achieves 98.3% density. collated in Table 2.

Volume 1 Issue 4 (2022) 6 https://doi.org/10.18063/msam.v1i4.24