Page 95 - MSAM-2-3

P. 95

Materials Science in Additive Manufacturing Validation of a novel ML model for AM-PSP

involves two pistons: one for supplying metal powder using bed” L-PBF processes, only the build platform is preheated

a recoater to create the powder layer, and the other to hold (typically 75 – 200°C). Due to the rapid heating and high

the fabricated parts. The chamber is filled with inert gas, cooling rate, residual stresses are inherently developed.

such as argon for reactive materials or nitrogen for non- Stress relief heat treatment is often required before the final

reactive materials. In addition, a flow of inert gas passes part is deployed in service. Table 1 shows the characteristic

over the powder layer to protect the part from oxidation, features of both PBF systems: L-PBF and EB-PBF processes.

remove spatter, and clear metal fumes generated along the When compared to the EB-PBF process, L-PBF

laser path.

processes have a lower build rate and scanning speed due

The main process parameters are the power of the laser to the electro-mechanical components involved in laser

source, scan speed, focus offset, hatch distance, and layer control. However, L-PBF offers better surface finish, higher

thickness. At present, available L-PBF systems often use accuracy, lower machine cost, and availability of larger

fiber lasers with 200 W to 1 kW peak power to selectively build volumes.

fuse the powder bed layer. The typical layer thickness value

ranges between 20 and 100 μm depending on the material 1.2. Directed energy deposition metal AM methods

size distribution. Unlike the EB-PBF process, in “cold- Directed energy deposition (DED) is another layer-by-layer

manufacturing technique to build metallic and functional

components. In contrast to PBF processes, where a power source

is used to melt a layer in the powder bed selectively, DED systems

involve a powder or wire feeding system that delivers material to

the melt pool created by the power source (like welding). In this

process, a melt pool is formed on the surface of the substrate

or previously deposited layer by using a high-energy power

source such as a laser beam, electron beam, or plasma arc. Using

numeric control (NC), the powder or wire is fed into the melt

pool along with synchronized motion stage control. A single

or multiple nozzle deposition heads can be used to deliver the

powder or wire. Like other AM processes, the toolpath for each

layer is generated by user-defined process parameters and a

sliced 3D CAD model. Several equipment manufacturers also

have their equipment labeled as DED processes, such as laser

cladding (LC), direct metal deposition (DMD), direct light

fabrication (DLF), laser direct casting (LDC), laser forming

(Lasform), shape deposition manufacturing (SDM), laser

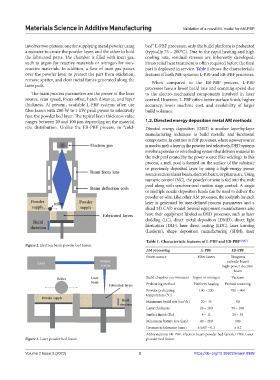

Table 1. Characteristic features of L‑PBF and EB‑PBF [14,15]

Figure 2. Electron beam-powder bed fusion.

AM processing L‑PBF EB‑PBF

Power source Fiber lasers Tungsten

cathode-based

high-power electron

beam

Build chamber environment Argon or nitrogen Vacuum

Preheating method Platform heating Preheat scanning

Powder preheating 100 – 200 700 – 900

temperature (°C)

3

Maximum build rate (cm /h) 20 – 35 80

Layer thickness 20 – 100 50 – 200

Surface finish (Ra) 4 – 11 25 – 35

Minimum feature size (μm) 40 – 200 100

Geometric tolerance (mm) ± 0.05 – 0.1 ± 0.2

Abbreviations: EB-PBF: Electron beam powder bed fusion; LPBF: Laser

Figure 3. Laser powder bed fusion. powder bed fusion.

Volume 2 Issue 3 (2023) 3 https://doi.org/10.36922/msam.0999