Page 100 - MSAM-4-3

P. 100

Materials Science in Additive Manufacturing Heterostructures of A131 steel by DED

A B C

D E F

Figure 5. Microstructure of AB A131 along ND (A-C) and TD (D-F). Yellow arrow (B-C): Particle defects. Scale bars: 100 µm (A, D and E); 50 µm (B and

F); 10 µm (C)

Abbreviations: AB: As-built; ND: Nominal direction; TD: Transverse direction

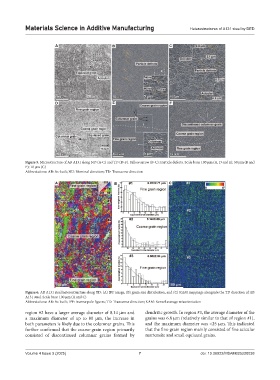

A B C

Figure 6. AB A131 steel heterostructure along TD: (A) IPF image; (B) grain size distribution, and (C) KAM mappings alongside the TD direction of AB

A131 steel. Scale bars: 100 µm (A and C)

Abbreviations: AB: As-built; IPF: Inverse pole figures; TD: Transverse direction; KAM: Kernel average misorientation

region #2 have a larger average diameter of 8.14 µm and dendritic growth. In region #3, the average diameter of the

a maximum diameter of up to 80 µm, the increase in grains was 6.8 µm (relatively similar to that of region #1),

both parameters is likely due to the columnar grains. This and the maximum diameter was <25 µm. This indicated

further confirmed that the coarse-grain region primarily that the fine-grain region mainly consisted of fine acicular

consisted of discontinued columnar grains formed by martensite and small equiaxed grains.

Volume 4 Issue 3 (2025) 7 doi: 10.36922/MSAM025220038