Page 97 - MSAM-4-3

P. 97

Materials Science in Additive Manufacturing Heterostructures of A131 steel by DED

A B

C D

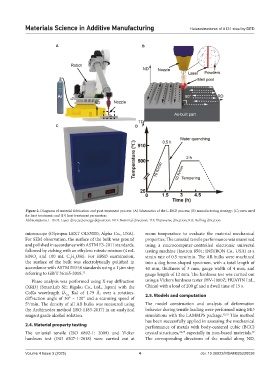

Figure 2. Diagrams of material fabrication and post-treatment process: (A) Schematics of the L-DED process; (B) manufacturing strategy; (C) oven used

for heat treatment; and (D) heat treatment parameters

Abbreviations: L-DED: Laser-directed energy deposition; ND: Nominal direction; TD: Transverse direction; RD: Rolling direction

microscope (Olympus LEXT OLS5000; Alpha Co., USA). room temperature to evaluate the material mechanical

For SEM observation, the surface of the bulk was ground properties. The uniaxial tensile performance was examined

and polished in accordance with ASTM E3-2011 standards, using a microcomputer-controlled electronic universal

followed by etching with an ethylene nitrate mixture (4 mL testing machine (Instron 8501; INSTRON Co., USA) at a

HNO and 100 mL C H OH). For EBSD examination, strain rate of 0.5 mm/min. The AB bulks were machined

2

5

3

the surface of the bulk was electrolytically polished in into a dog bone-shaped specimen, with a total length of

accordance with ASTM E1558 standards using a 1 µm step 40 mm, thickness of 3 mm, gauge width of 4 mm, and

referring to GB/T 36165-2018. 31 gauge length of 12 mm. The hardness test was carried out

Phase analysis was performed using X-ray diffraction using a Vickers hardness tester (HV-1000Z; HUAYIN Ltd.,

(XRD) (SmartLab SE; Rigaku Co., Ltd., Japan) with the China) with a load of 200 gf and a dwell time of 15 s.

CoKa wavelength (λ Ka) of 1.79 Å, over a rotation- 2.5. Models and computation

Co

diffraction angle of 30° – 120° and a scanning speed of

5°/min. The density of all AB bulks was measured using The model construction and analysis of deformation

the Archimedes method (ISO 1183-2017) in an analytical behavior during tensile loading were performed using MD

reagent grade alcohol solution. simulations with the LAMMPS package. 32,33 This method

has been successfully applied in assessing the mechanical

2.4. Material property testing performance of metals with body-centered cubic (BCC)

36

The uniaxial tensile (ISO 6892-1: 2009) and Vicker crystal structures, 34,35 especially in iron-based materials.

hardness test (ISO 6507-1-2018) were carried out at The corresponding directions of the model along ND,

Volume 4 Issue 3 (2025) 4 doi: 10.36922/MSAM025220038