Page 55 - ESAM-1-2

P. 55

Engineering Science in

Additive Manufacturing Multi-material additive manufacturing of metals

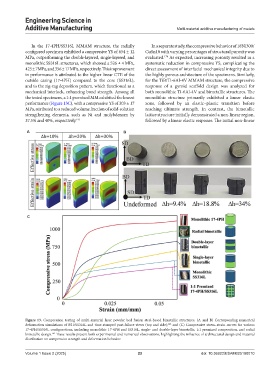

In the 17-4PH/SS316L MMAM structure, the radially In a separate study, the compressive behavior of 18Ni300/

configured specimen exhibited a compressive YS of 654 ± 12 CuSn10 with varying percentages of structural porosity was

MPa, outperforming the double-layered, single-layered, and evaluated. As expected, increasing porosity resulted in a

176

monolithic SS316L structures, which showed a 526 ± 4 MPa, systematic reduction in compressive YS, complicating the

425 ± 7MPa, and 356 ± 17 MPa, respectively. This improvement direct assessment of interfacial mechanical integrity due to

in performance is attributed to the higher linear CTE of the the highly porous architecture of the specimens. Similarly,

outside casing (17-4PH) compared to the core (SS316L), for the TiB/Ti-6Al-4V MMAM structure, the compressive

and to the zig-zag deposition pattern, which functioned as a response of a gyroid scaffold design was analyzed for

mechanical interlock, enhancing bond strength. Among all both monolithic Ti-6Al-4V and bimetallic structures. The

the tested specimens, a 1:1 premixed MM exhibited the lowest monolithic structure primarily exhibited a linear elastic

performance (Figure 13C), with a compressive YS of 303 ± 17 zone, followed by an elastic–plastic transition before

MPa, attributed to a reduced volume fraction of solid-solution reaching ultimate strength. In contrast, the bimetallic

strengthening elements, such as Ni and molybdenum by lattice structure initially demonstrated a non-linear region,

37.5% and 40%, respectively. 147 followed by a linear elastic response. The initial non-linear

A B

C

Figure 13. Compression testing of multi-material laser powder bed fusion steel-based bimetallic structures. (A and B) Corresponding numerical

deformation simulations of P21/SS316L and time-stamped post-failure views (top and side); and (C) Compressive stress–strain curves for various

166

17-4PH/SS316L configurations, including monolithic 17-4PH and SS316L, single- and double-layer bimetallic, 1:1 premixed composition, and radial

bimetallic design. These results present both experimental and numerical observations, highlighting the influence of architectural design and material

147

distribution on compressive strength and deformation behavior.

Volume 1 Issue 2 (2025) 23 doi: 10.36922/ESAM025180010