Page 58 - ESAM-1-2

P. 58

Engineering Science in

Additive Manufacturing Multi-material additive manufacturing of metals

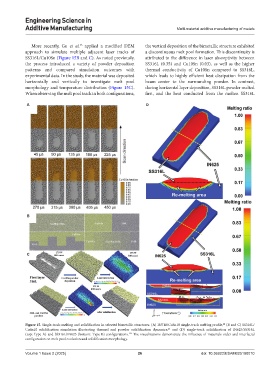

More recently, Gu et al. applied a modified DEM the vertical deposition of the bimetallic structure exhibited

23

approach to simulate multiple adjacent laser tracks of a discontinuous melt pool formation. This discontinuity is

SS316L/Cu10Sn (Figure 15B and C). As noted previously, attributed to the difference in laser absorptivity between

the process introduced a variety of powder deposition SS316L (0.35) and Cu10Sn (0.03), as well as the higher

patterns and compared simulation outcomes with thermal conductivity of Cu10Sn compared to SS316L,

experimental data. In the study, the material was deposited which leads to highly efficient heat dissipation from the

horizontally and vertically to investigate melt pool beam center to the surrounding powder. In contrast,

morphology and temperature distribution (Figure 15C). during horizontal layer deposition, SS316L powder melted

When observing the melt pool track in both configurations, first, and the heat conducted from the molten SS316L

A D

B

C

Figure 15. Single-track melting and solidification in selected bimetallic structures. (A) IN718/CuSn10 single-track melting profile; (B and C) SS316L/

20

CuSn10 solidification simulation illustrating thermal and powder solidification dynamics; and (D) single-track solidification of IN625/SS316L

23

(top: Type-A) and SS316L/IN625 (bottom: Type-B) configurations. The visualizations demonstrate the influence of materials order and interfacial

132

configuration on melt pool evolution and solidification morphology.

Volume 1 Issue 2 (2025) 26 doi: 10.36922/ESAM025180010