Page 307 - IJB-10-1

P. 307

International Journal of Bioprinting Low-cost quad-extrusion 3D bioprinting system

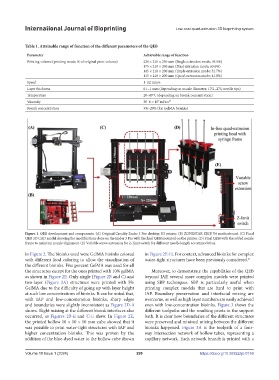

Table 1. Attainable range of function of the different parameters of the QEB

Parameter Achievable range of function

Printing volume (printing mode; % of original print volume) 220 × 210 × 250 mm (Single extrusion mode; 95.5%)

175 × 210 × 200 mm (Dual extrusion mode; 63.6%)

145 × 210 × 200 mm (Triple extrusion mode; 52.7%)

115 × 210 × 200 mm (Quad-extrusion mode; 41.8%)

Speed 1–12 mm/s

Layer thickness 0.1–1 mm (depending on nozzle diameter; 17G–27G needle tips)

Temperature 20–40°C (depending on bioink concentration)

7

Viscosity 30–6 × 10 mPa·s 45

Bioink concentration 3%–20% (for GelMA bioinks)

Figure 1. QEB development and components. (A) Original Creality Ender 3 Pro desktop 3D printer. (B) ZONESTAR ZRIB V6 motherboard. (C) Final

QEB 3D CAD model showing the modifications done on the Ender 3 Pro with the final QEH mounted on the printer. (D) Final QEH with the added nozzle

frame to maintain nozzle alignment. (E) Variable screw extension for Z-limit switch for different needle length accommodation.

in Figure 2. The bioinks used were GelMA bioinks colored in Figure 2E-iii. For context, advanced bioinks for complex

with different food coloring to allow the visualization of water-tight structures have been previously considered. 41

the different bioinks. Five percent GelMA was used for all

the structures except for the ones printed with 10% gelMA Moreover, to demonstrate the capabilities of the QEB

as shown in Figure 2E. Only single (Figure 2B and C) and beyond IAP, several more complex models were printed

two-layer (Figure 2A) structures were printed with 5% using SBP techniques. SBP is particularly useful when

GelMA due to the difficulty of going up with layer height printing complex models that are hard to print with

at such low concentrations of bioinks. It can be noted that, IAP. Boundary preservation and interfacial mixing are

with IAP and low-concentration bioinks, sharp edges overcome, as well as high layer numbers are easily achieved

and boundaries were slightly inconsistent as Figure 2D-ii even with low-concentration bioinks. Figure 3 shows the

shows. Slight mixing at the different bioink interfaces also different toolpaths and the resulting prints in the support

occurred, as Figures 2B-ii and C-ii show. In Figure 2E, bath. It is clear how boundaries of the different structures

the printed hollow 10 × 10 × 10 mm cube showed that it were preserved and minimal mixing between the different

was possible to print water-tight structures with IAP and bioinks happened. Figure 3A is the toolpath of a four-

higher concentration bioinks. This was proven by the way intersection network of hollow tubes, representing a

addition of the blue-dyed water to the hollow cube shown capillary network. Each network branch is printed with a

Volume 10 Issue 1 (2024) 299 https://doi.org/10.36922/ijb.0159