Page 310 - IJB-10-1

P. 310

International Journal of Bioprinting Low-cost quad-extrusion 3D bioprinting system

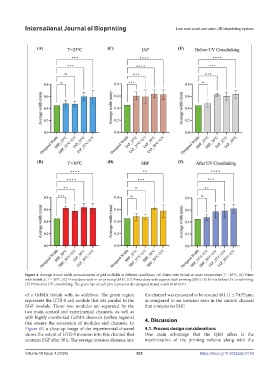

Figure 4. Average strand width measurements of grid scaffolds at different conditions. (A) Prints with bioink at room temperature T = 25°C. (B) Prints

with bioink at T = 30°C. (C) Prints done with in-air printing (IAP). (D) Prints done with support bath printing (SBP). (E) Prints before UV crosslinking.

(F) Prints after UV crosslinking. The green bar of each plot represents the designed strand width (0.45 mm).

of a GelMA bioink with no additives. The green region the channel was measured to be around 481.11 ± 74.55 µm,

represents the HTR-8 cell module that sits parallel to the as compared to no invasion seen in the control channel

EGF module. Those two modules are separated by the that contains no EGF.

two main control and experimental channels, as well as

with highly crosslinked GelMA channels (yellow regions) 4. Discussion

that ensure the separation of modules and channels. In

Figure 6F, a close-up image of the experimental channel 4.1. Process design considerations

shows the extent of HTR-8 invasion into this channel that One main advantage that the QEB offers is the

contains EGF after 30 h. The average invasion distance into maximization of the printing volume along with the

Volume 10 Issue 1 (2024) 302 https://doi.org/10.36922/ijb.0159