Page 542 - IJB-10-2

P. 542

International Journal of Bioprinting Bottom-up and top-down VAT photopolimerization

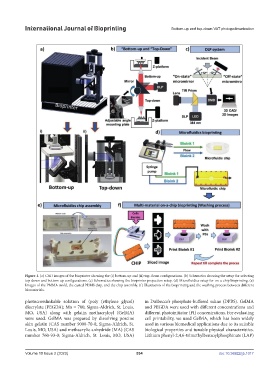

Figure 1. (a) CAD images of the bioprinter showing the (i) bottom-up and (ii) top-down configurations. (b) Schematics showing the setup for selecting

top-down and bottom-up configurations. (c) Schematics showing the bioprinter projection setup. (d) Microfluidics setup for on-a-chip bioprinting. (e)

Images of the PMMA mold, the casted PDMS chip, and the chip assembly. (f) Illustration of the bioprinting and the washing process between different

biomaterials.

photocrosslinkable solution of (poly (ethylene glycol) in Dulbecco’s phosphate-buffered saline (DPBS). GelMA

diacrylate (PEGDA); Mn = 700; Sigma-Aldrich, St. Louis, and PEGDA were used with different concentrations and

MO, USA) along with gelatin methacryloyl (GelMA) different photoinitiator (PI) concentrations. For evaluating

were used. GelMA was prepared by dissolving porcine cell printability, we used GelMA, which has been widely

skin gelatin (CAS number 9000-70-8; Sigma-Aldrich, St. used in various biomedical applications due to its suitable

Louis, MO, USA) and methacrylic anhydride (MA) (CAS biological properties and tunable physical characteristics.

number 760-93-0; Sigma-Aldrich, St. Louis, MO, USA) Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP)

Volume 10 Issue 2 (2023) 534 doi: 10.36922/ijb.1017