Page 545 - IJB-10-3

P. 545

International Journal of Bioprinting Engineered 3D-printed PVA vascular grafts

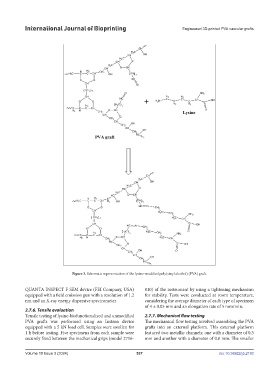

Figure 3. Schematic representation of the lysine-modified poly(vinyl alcohol) (PVA) graft.

QUANTA INSPECT F SEM device (FEI Company, USA) 010) of the instrument by using a tightening mechanism

equipped with a field emission gun with a resolution of 1.2 for stability. Tests were conducted at room temperature,

nm and an X-ray energy dispersive spectrometer. considering the average diameter of each type of specimen

of 4 ± 0.05 mm and an elongation rate of 5 mm/min.

2.7.6. Tensile evaluation

Tensile testing of lysine-biofunctionalized and unmodified 2.7.7. Mechanical flow testing

PVA grafts was performed using an Instron device The mechanical flow testing involved assembling the PVA

equipped with a 5 kN load cell. Samples were swollen for grafts into an external platform. This external platform

1 h before testing. Five specimens from each sample were featured two metallic channels: one with a diameter of 0.3

securely fixed between the mechanical grips (model 2716- mm and another with a diameter of 0.8 mm. The smaller

Volume 10 Issue 3 (2024) 537 doi: 10.36922/ijb.2193