Page 599 - IJB-10-3

P. 599

International Journal of Bioprinting Five-axis printer for hybrid 3D scaffolds

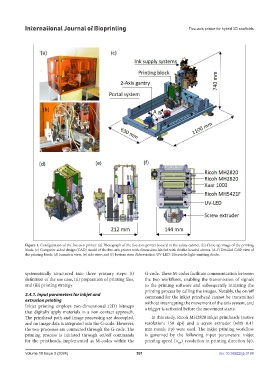

Figure 1. Configuration of the five-axis printer. (a) Photograph of the five-axis printer housed in the safety cabinet. (b) Close-up image of the printing

block. (c) Computer-aided design (CAD) model of the five-axis printer with dimensions labeled with double-headed arrows. (d–f) Detailed CAD view of

the printing block: (d) isometric view; (e) side view; and (f) bottom view. Abbreviation: UV-LED: Ultraviolet light-emitting diode.

systematically structured into three primary steps: (i) G-code. These M-codes facilitate communication between

definition of the use case, (ii) preparation of printing files, the two workflows, enabling the transmission of signals

and (iii) printing strategy. to the printing software and subsequently initiating the

printing process by calling the images. Notably, the on/off

2.4.1. Input parameters for inkjet and command for the inkjet printhead cannot be transmitted

extrusion printing without interrupting the movement of the axis system, and

Inkjet printing employs two-dimensional (2D) bitmaps a trigger is activated before the movement starts.

that digitally apply materials in a non-contact approach.

The printhead path and image processing are decoupled, In this study, Ricoh MH2820 inkjet printheads (native

and no image data is integrated into the G-code. However, resolution: 150 dpi) and a screw extruder (with 0.41

the two processes are connected through the G-code. The mm nozzle tip) were used. The inkjet printing workflow

printing process is initiated through on/off commands is governed by the following input parameters: inkjet

for the printheads, implemented as M-codes within the printing speed (ν ) resolution in printing direction (ϕ),

IJP ,

Volume 10 Issue 3 (2024) 591 doi: 10.36922/ijb.3189