Page 103 - IJB-6-4

P. 103

Silva, et al.

for cell-laden hydrogel), which is continuously Germany) solution was pre-crosslinked with

increasing from Nozzle 1 to Nozzle 3. 20 mmol/l CaCO (Calcium carbonate precipitated

3

for analysis EMSURE , CAS 471-34-1,

®

2.2 Preparation of hydrogels Merck KGaA, Darmstadt, Germany) and 40 mmol/

For each of the channels (a, b, and c) described l GDL (CAS 90-80-2, Merck KGaA, Darmstadt,

in section 2.1, different materials were used Germany) at 4°C. After stirring continuously for

during the printing process. While channel c was 48 h, the hydrogel was allowed to warm up to

perfused with CaCl solution, the other channels room temperature and was subsequently mixed

2

were perfused with two different hydrogel with cells (see section 2.4).

compositions. 2.3 Setup for 3D bioprinting with coaxial

Channel a was used to print a support structure nozzles

in the core, based on a methylcellulose-gelatin

sacrificial ink, as described by Dranseikiene et al. A commercially available fused deposition modeling

[24]

Briefly, the sacrificial biomaterial ink is composed 3D printer (Anycubic Prusa I3, ANYCUBIC 3D

of 9 % (w/v) Methylcellulose (Sigma, USA) and Printing, Shenzhen, China) was customized to allow

5 % (w/v) gelatin (Sigma, USA) and was shown to the controlled deposition of hydrogels (Figure 2).

exhibit good support characteristics after printing, For this purpose, three independent piston-driven

while dissolving in culture conditions after 1 week. extrusion systems were coupled to the machine and

The hydrogel used for printing with cells the feed rate (mm/s) was translated into pressure

was an alginate-based bioink, prepared with a units (kPa) with the aid of an external system. Next,

pre-crosslinking technique utilizing CaCO and printheads suited for 12 mL Luer-lock syringes

3

D-Glucono-δ-lactone (GDL). Concisely, a 2 % were adapted to the extrusion systems and their

(w/v) alginate (VIVAPHARM alginate PH176, outlet tips were connected to the inlets of the 3D

®

JRS PHARMA GmbH & Co. KG, Rosenberg, printed coaxial nozzles.

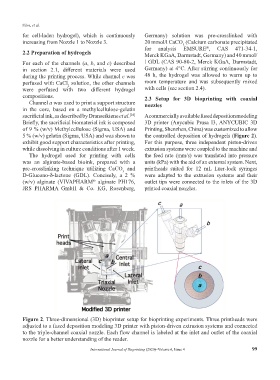

Figure 2. Three-dimensional (3D) bioprinter setup for bioprinting experiments. Three printheads were

adjusted to a fused deposition modeling 3D printer with piston-driven extrusion systems and connected

to the triple-channel coaxial nozzle. Each flow channel is labeled at the inlet and outlet of the coaxial

nozzle for a better understanding of the reader.

International Journal of Bioprinting (2020)–Volume 6, Issue 4 99