Page 349 - IJB-10-6

P. 349

International Journal of Bioprinting Collagen hydrolysate-loaded ODMA/PEGDMA scaffold

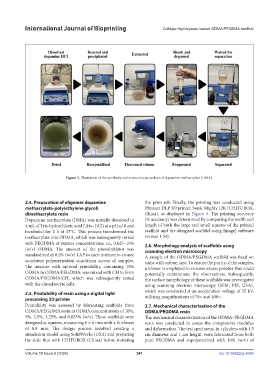

Figure 2. Illustration of the synthesis and extraction procedure of dopamine methacrylate (DMA).

2.4. Preparation of oligomer dopamine the print job. Finally, the printing was conducted using

methacrylate-poly(ethylene glycol) Phrozen DLP 3D printer, Sonic Mighty 12K (CHITUBOX,

dimethacrylate resin China), as displayed in Figure 3. The printing accuracy

Dopamine methacrylate (DMA) was initially dissolved in (% accuracy) was determined by comparing the width and

4 mL of Tris-hydrochloric acid (Tris–HCl) at a pH of 8 and length of both the large and small squares of the printed

incubated for 2 h at 37°C. This process transformed the scaffold and the designed scaffold using ImageJ software

methacrylate into ODMA, which was subsequently mixed version 1.54j.

with PEGDMA at various concentrations, i.e., 0.625–10% 2.6. Morphology analysis of scaffolds using

(w/v) ODMA. The amount of the photoinitiator was scanning electron microscopy

standardized at 0.5% (w/v) LAP in each mixture to ensure A sample of the ODMA/PEGDMA scaffold was fixed on

consistent polymerization conditions across all samples. stubs with carbon tape. To ensure the purity of the samples,

The mixture with optimal printability, containing 10% a blower is employed to remove excess powder that could

ODMA in ODMA/PEGDMA, was mixed with CH to form potentially contaminate the observations. Subsequently,

ODMA/PEGDMA/CH, which was subsequently tested the surface morphology of these scaffolds was investigated

with the chondrocyte cells. using scanning electron microscopy (SEM; FEI, USA),

2.5. Printability of resin using a digital light which was conducted at an acceleration voltage of 15 kV,

processing 3D printer utilizing magnifications of 70× and 400×.

Printability was assessed by fabricating scaffolds from 2.7. Mechanical characterization of the

ODMA/PEGDMA resin at ODMA concentrations of 10%, ODMA/PEGDMA resin

5%, 2.5%, 1.25%, and 0.625% (w/v). These scaffolds were The mechanical characterization of the ODMA–PEGDMA

designed as squares, measuring 6 × 6 mm with a thickness resin was conducted to assess the compressive modulus

of 0.8 mm. The design process involved creating a and deformation. The test specimens, in cylinders with 1.5

simulation model using SolidWorks (USA) and preparing cm diameter and 1 cm height, were fabricated from both

the slide files with CHITUBOX (China) before initiating pure PEGDMA and copolymerized with 10% (w/v) of

Volume 10 Issue 6 (2024) 341 doi: 10.36922/ijb.4385