Page 36 - IJB-7-2

P. 36

Additively Manufactured NiTi Implants

conventional manufacturing technology. These unique life of edge samples is the shortest. Subsequently, Bayati

precipitates and dislocations lead to the unique phase et al. [123] first adopted a self-heating approach to analyze

transformation behavior and mechanical properties of the high-cycle fatigue behavior of samples manufactured

SLM-NiTi [124] . in the horizontal direction, as Figure 27 shows. They

evaluated the fatigue limits of the original and pre-

4.4. Fatigue behavior strained samples by the self-heating method. It seems

Fatigue failure is one of the main failure modes of dense and that the pre-strained part exhibited a longer fatigue life

porous NiTi. Transformation temperature, microstructure compared to the original sample. The authors considered

defects, load types, the strength and volume fraction of that for a given load level, the mechanical dissipation of

austenite and martensite, and the unwanted second phase the original sample is much larger than the pre-strained

are all factors that affect the fatigue life . Bayati et al. [123] sample, making the cyclic load of the original sample

[2]

also investigated the low-cycle fatigue behavior of NiTi accompanied by more fatigue damage and reducing the

parts manufactured in three different build orientations. fatigue limit.

The fatigue life of the samples manufactured at 45° Speirs et al. [126] studied the compression fatigue

relative to the build plate is the longest, while the fatigue behavior of SLM-NiTi scaffolds with three different

A B

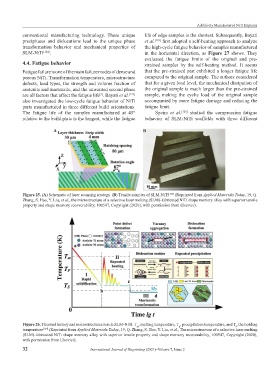

Figure 25. (A) Schematic of laser scanning strategy. (B) Tensile samples of SLM-NiTi [124] (Reprinted from Applied Materials Today, 19, Q.

Zhang, S. Hao, Y. Liu, et al., the microstructure of a selective laser melting (SLM)-fabricated NiTi shape memory alloy with superior tensile

property and shape memory recoverability, 100547, Copyright (2020), with permission from Elsevier).

Figure 26. Thermal history and microstructures inside SLM-NiTi. T , melting temperature, T , precipitation temperature, and T , the holding

m

p

s

temperature [124] (Reprinted from Applied Materials Today, 19, Q. Zhang, S. Hao, Y. Liu, et al., The microstructure of a selective laser melting

(SLM)-fabricated NiTi shape memory alloy with superior tensile property and shape memory recoverability, 100547, Copyright (2020),

with permission from Elsevier).

32 International Journal of Bioprinting (2021)–Volume 7, Issue 2