Page 165 - IJB-7-4

P. 165

Lee, et al.

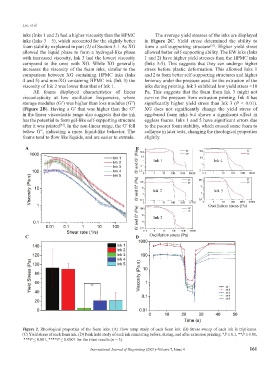

inks (Inks 1 and 2) had a higher viscosity than the HPMC The average yield stresses of the inks are displayed

inks (Inks 3 – 5), which accounted for the slightly better in Figure 2C. Yield stress determined the ability to

foam stability explained in part (2) of Section 3.1. As XG form a self-supporting structure . Higher yield stress

[33]

allowed the liquid phase to form a hydrogel-like phase allowed better self-supporting ability. The EW inks (Inks

with increased viscosity, Ink 3 had the lowest viscosity 1 and 2) have higher yield stresses than the HPMC inks

compared to the ones with XG. While XG generally (Inks 3-5). This suggests that they can undergo higher

increases the viscosity of the foam inks, similar to the stress before plastic deformation. This allowed Inks 1

comparison between XG containing HPMC inks (Inks and 2 to form better self-supporting structures and higher

4 and 5) and non-XG containing HPMC ink (Ink 3) the leniency under the pressure used for the extrusion of the

viscosity of Ink 2 was lower than that of Ink 1. inks during printing. Ink 3 exhibited low yield stress <10

All foams displayed characteristics of linear Pa. This suggests that the foam from Ink 3 might not

viscoelasticity at low oscillation frequencies, where survive the pressure from extrusion printing. Ink 4 has

storage modulus (G’) was higher than loss modulus (G”) significantly higher yield stress than Ink 3 (P < 0.01).

(Figure 2B). Having a G’ that was higher than the G” XG does not significantly change the yield stress of

in the linear viscoelastic range also suggests that the ink egg-based foam inks but shows a significant effect in

has the potential to form gel-like self-supporting structure eggless foams. Inks 1 and 5 have significant errors due

after it was printed . In the non-linear range, the G’ fell to the poorer foam stability, which caused some foam to

[33]

below G”, indicating a more liquid-like behavior. The collapse in later tests, changing the rheological properties

foams tend to flow like liquids, and are easier to extrude. slightly.

A B

C D

Figure 2. Rheological properties of the foam inks. (A) Flow ramp study of each foam ink. (B) Stress sweep of each ink in triplicates.

(C) Yield stress of each foam ink. (D) Peak hold study of each ink simulating before, during, and after extrusion printing. *P ≤ 0.1, **P ≤ 0.01,

***P ≤ 0.001, ****P ≤ 0.0001 for the t-test results (n = 3).

International Journal of Bioprinting (2021)–Volume 7, Issue 4 161