Page 180 - IJB-7-4

P. 180

3D Printing Custom Shoe Sole

A mode due to the effects of the magnitude and time of

impact force on the shoe midsole.

It is an undeniable that denser infill patterns supply

stronger support to a fabrication to absorb more energy

or less the crushing. However, they consume more

printing time, energy, material, and subsequent waste.

Therefore, this method of customizing the shoe midsole

in terms of individual’s specifications but using the

B same amount of materials is efficiency in the reduction

of material usage and time of 3D printing. This study

proves the feasibility of an adaptive infill patterns

application in stiffness and damping tuning required in

custom shoes industry. Further clinical and experimental

measurements are required as future directions.

4. Conclusions

C In this work, various shoe midsoles were designed by

considering different activities of person, such as walking,

running, and jumping, and for this trend, a 3D printable

viscoelastic material was selected and subjected to low

velocity impact test that resulted in a graph of load over time.

This load versus time graph gives the idea about how shoe

midsole is helpful to reduce the plantar pressure on people

based on their specific activity. The novelty of the present

study compared to other currently commercial models is

investigation of functional customization that does more

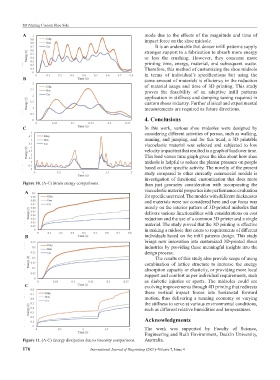

Figure 10. (A-C) Strain energy comparisons. than just geometry consideration with incorporating the

A viscoelastic material properties into performance evaluation

for specific user need. The models with different thicknesses

and materials were not considered here and our focus was

merely on the interior pattern of 3D-printed midsoles that

delivers various functionalities with considerations on cost

reduction and the use of a common 3D printer and a single

material. The study proved that the 3D printing is effective

in making a midsole that caters to requirements of different

B individuals based on the infill patterns design. This study

brings new innovation into customized 3D-printed shoes

industries by providing these meaningful insights into the

design process.

The results of this study also provide scope of using

combination of lattice structure to increase the energy

absorption capacity or elasticity, or providing more local

support and comfort as per individual requirements, such

as diabetic injuries or sports. The midsoles could see

C evolving improvements through 4D printing that redirects

these vertical impact forces into horizontal forward

motion, thus delivering a running economy or varying

the stiffness to serve at various environmental conditions,

such as different relative humidities and temperatures.

Acknowledgments

The work was supported by Faculty of Science,

Engineering and Built Environment, Deakin University,

Figure 11. (A-C) Energy dissipation due to viscosity comparisons. Australia.

176 International Journal of Bioprinting (2021)–Volume 7, Issue 4