Page 156 - IJB-8-1

P. 156

Design Criteria for Patient-Specific Mandibular Implant

used to filter the influence of a certain feature size with a j j

maximum or minimum value (Table 3). Z sd . j ave wherej AB BB , CB T (2)

,

,

,

j

L

L

n 9 Z ( j Z)

SDZ j 1 100. (3)

n ( 1)

Where, sd value is one of the nine segmental bone

length, width, and height dimensions.

The worst mandible structure case, that is, the

structural weakest case can be filtered through calculating

the V and SDZ values. The mandible with the largest V

value and SDZ value definition <1.0 was the worst case,

and their corresponding values were 13.71 and 0.66,

respectively (Table 3).

2.2. Design criteria for reconstructed implant

with large defect segment

Solid models of A, B, and C regions according to the

definitions in Table 1 were constructed and divided in

the CAD system (Creo Parametric v2.0, PTC, Needham,

MA, USA) based on the previously selected worst

mandible structure. Large mandible defects including

single segment C and B and combined A+B segment were

defined and designed with corresponding reconstructed

implants according to the following five design points:

(i) The thickness of the implant shell was set to 0.5 mm;

(ii) the height of the implant was designed to be 1/2 of

the height of the bone segment, and the bone graft space

for postoperative prosthesis is reserved at the top for

subsequent follow-up; (iii) the thickness of the implant

M 1 3 was designed to be 2/3 of the bone segment thickness to

M=F×LB; HB ; I TB HB* allow space for the flap, vascular pedicle, and soft tissue

2

to pass through; (iv) the implant needs to be designed

I 64

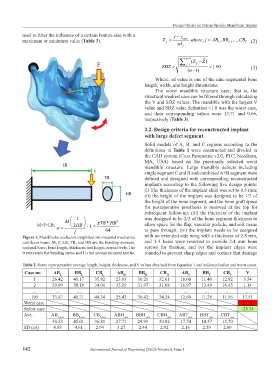

Figure 1. Mandibular occlusion simplified into material mechanics with an extended side wing with a thickness of 2.8 mm,

cantilever beam. M, F, LB, TB, and HB are the bending moment, and 3-5 holes were reserved to provide 2.4 mm bone

occlusal force, bone length, thickness, and height, respectively. The screws for fixation; and (v) the implant edges were

σ represents the bending stress and I is the second moment inertia. rounded to prevent sharp edges and corners that damage

Table 2. Some representative average length, height, thickness, and V values obtained from Equation 1 and indicated safest and worst cases.

Case no. AB L BB L CB L AB H BB H CB H AB T BB T CB T V

1 26.42 48.17 35.82 23.83 30.21 32.61 16.00 11.40 12.92 3.54

2 39.99 50.18 34.01 33.19 31.97 31.08 16.97 13.49 16.45 1.14

… … … … … … … … … … …

105 33.87 48.71 40.34 25.43 30.42 34.24 12.60 11.28 11.56 17.51

Worst case 13.71

Safest case -25.74

Ave. AB L.ave BB L.ave CB L.ave ABH .ave BBH .ave CBH .ave ABT .ave BBT .ave CBT .ave

34.53 45.01 36.81 27.71 29.91 30.82 17.74 14.57 15.70

SD (sd ) 4.88 4.61 2.94 3.27 2.44 2.92 2.16 2.59 2.09

j

142 International Journal of Bioprinting (2022)–Volume 8, Issue 1