Page 177 - IJB-8-1

P. 177

Aihemaiti, et al.

A B C

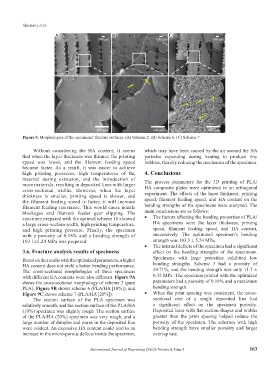

Figure 9. Morphologies of the specimens’ fracture surfaces. (A) Scheme 2. (B) Scheme 6. (C) Scheme 7.

Without considering the HA content, it seems which may have been caused by the air around the HA

that when the layer thickness was thinner, the printing particles expanding during heating to produce tiny

speed was lower, and the filament feeding speed bubbles, thereby reducing the mechanics of the specimen.

became faster. As a result, it was easier to achieve

high printing pressures, high temperatures of the 4. Conclusions

material during extrusion, and the introduction of The process parameters for the 3D printing of PLA/

more materials, resulting in deposited lines with larger HA composite plates were optimized in an orthogonal

cross-sectional widths. However, when the layer

thickness is smaller, printing speed is slower, and experiment. The effects of the layer thickness, printing

the filament feeding speed is faster, it will increase speed, filament feeding speed, and HA content on the

filament feeding resistance. This would cause nozzle bending strengths of the specimens were analyzed. The

blockages and filament feeder gear slipping. The main conclusions are as follows:

specimen prepared with the optimal scheme 10 showed • The factors affecting the bending properties of PLA/

a large cross-section width, high printing temperature, HA specimens were the layer thickness, printing

and high printing pressure. Finally, the specimen speed, filament feeding speed, and HA content,

with a porosity of 0.18% and a bending strength of successively. The optimized specimen’s bending

103.1±5.24 MPa was prepared. strength was 103.1 ± 5.24 MPa.

• The internal defects of the specimen had a significant

3.6. Fracture analysis results of specimens effect on the bending strengths of the specimens.

Based on the results with the optimized parameters, a higher Specimens with large porosities exhibited low

HA content does not yield a better bending performance. bending strengths. Scheme 3 had a porosity of

The cross-sectional morphologies of three specimens 49.71%, and the bending strength was only 11.7 ±

with different HA contents were also different. Figure 9A 0.35 MPa. The specimen printed with the optimized

shows the cross-sectional morphology of scheme 2 (pure parameters had a porosity of 0.18% and a maximum

PLA), Figure 9B shows scheme 6 (PLA/HA [10%]), and bending strength.

Figure 9C shows scheme 7 (PLA/HA [20%]). • When the print spacing was consistent, the cross-

The section surface of the PLA specimen was sectional size of a single deposited line had

relatively smooth, and the section surface of the PLA/HA a significant effect on the specimen porosity.

(10%) specimen was slightly rough. The section surface Deposited lines with flat section shapes and widths

of the PLA/HA (20%) specimen was very rough, and a greater than the print spacing helped reduce the

large number of dimples and pores in the deposited line porosity of the specimen. The schemes with high

were evident. An excessive HA content could lead to an bending strength have smaller porosity and larger

increase in the micro-porous defects inside the specimen, overlap rate.

International Journal of Bioprinting (2022)–Volume 8, Issue 1 163