Page 18 - IJB-8-1

P. 18

Additive Manufactured Beta-Titanium Alloys

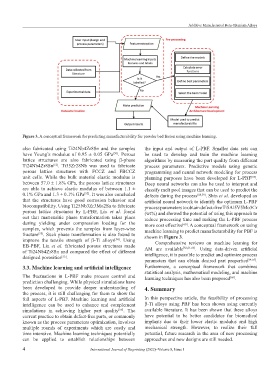

Figure 3. A conceptual framework for predicting manufacturability for powder bed fusion using machine learning.

also fabricated using Ti24Nb4Zr8Sn and the samples the input and output of L-PBF. Smaller data sets can

have Young’s modulus of 0.95 ± 0.05 GPa [50] . Porous be used to develop and train the machine learning

lattice structures are also fabricated using β-phase algorithms by measuring the part quality from different

Ti24Nb4Zr8Sn [51] . Ti35Zr28Nb was used to fabricate process parameters. Predictive models using genetic

porous lattice structures with FCCZ and FBCCZ programming and neural network modeling for process

unit cells. While the bulk material elastic modulus is planning purposes have been developed for L-PBF .

[57]

between 57.0 ± 1.8% GPa, the porous lattice structures Deep neural networks can also be used to interpret and

are able to achieve elastic modulus of between 1.1 ± classify melt pool images that can be used to predict the

0.1% GPa and 1.3 ± 0.1% GPa [52] . It was also concluded defects during the process [58,59] . Shin et al. developed an

that the structures have good corrosion behavior and artificial neural network to identify the optimum L-PBF

biocompatibility. Using Ti25Nb3Zr3Mo2Sn to fabricate process parameters to obtain defect-free Ti5Al5V5Mo3Cr

porous lattice structures by L-PBF, Liu et al. found (wt%) and showed the potential of using this approach to

out that martensitic phase transformation takes place reduce processing time and making the L-PBF process

during yielding under compression loading for the more cost effective . A conceptual framework on using

[60]

samples, which prevents the samples from layer-wise machine learning to predict manufacturability for PBF is

fracture [53] . Such phase transformation is also found to shown in Figure 3.

improve the tensile strength of β-Ti alloys [54] . Using Comprehensive reviews on machine learning for

EB-PBF, Liu et al. fabricated porous structures made AM are available [56,61-63] . Using data-driven artificial

of Ti24Nb4Zr8Sn and compared the effect of different

designed porosities [55] . intelligence, it is possible to predict and optimize process

parameters that can obtain desired part properties [64,65] .

3.3. Machine learning and artificial intelligence Furthermore, a conceptual framework that combines

statistical analysis, mathematical modeling, and machine

The fluctuations in L-PBF make process control and learning techniques has also been proposed .

[66]

prediction challenging. While physical simulations have

been developed to provide deeper understanding of 4. Summary

the process, it is still challenging for them to show the

full aspects of L-PBF. Machine learning and artificial In this perspective article, the feasibility of processing

intelligence can be used to enhance and complement β-Ti alloys using PBF has been shown using currently

simulations in achieving higher part quality . The available literature. It has been shown that these alloys

[56]

current practice to obtain defect-free parts, or commonly have potential to be better candidates for biomedical

known as the process parameters optimization, involves implants due to their lower elastic modulus and high

multiple rounds of experiments which are costly and mechanical strength. However, to realize their full

time intensive. Machine learning techniques potentially potential, future research in the area of new processing

can be applied to establish relationships between approaches and new designs are still needed.

4 International Journal of Bioprinting (2022)–Volume 8, Issue 1