Page 242 - IJB-9-1

P. 242

International Journal of Bioprinting 3D printing of smart constructs for precise medicine

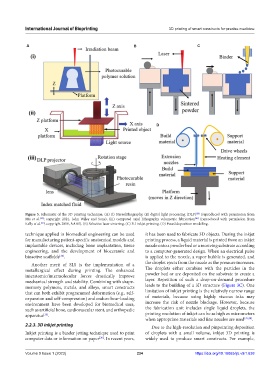

A B C

D

Figure 3. Schematic of the 3D printing technique. (A) (i) Stereolithography, (ii) digital light processing (DLP) (reproduced with permission from

[25]

Mu et al. ; copyright 2021, John Wiley and Sons), (iii) computed axial lithography volumetric fabrication (reproduced with permission from

[25]

[26]

Kelly et al. ; copyright 2019, AAAS). (B) Selective laser sintering. (C) 3D inkjet printing. (D) Fused deposition modeling.

[26]

technique applied in biomedical engineering can be used it has been used to fabricate 3D objects. During the inkjet

for manufacturing patient-specific anatomical models and printing process, a liquid material is printed from an inkjet

implantable devices, including bone implantation, tissue nozzle onto a powder bed or a receiving substrate according

engineering, and the development of bioceramic and to a computer-generated design. When an electrical pulse

bioactive scaffolds . is applied to the nozzle, a vapor bubble is generated, and

[34]

Another merit of SLS is the implementation of a the droplet ejects from the nozzle as the pressure increases.

metallurgical effect during printing. The enhanced The droplets either combine with the particles in the

interatomic/intermolecular forces drastically improve powder bed or are deposited on the substrate to create a

mechanical strength and stability. Combining with shape- layer. Repetition of such a drop-on-demand procedure

memory polymers, metals, and alloys, smart constructs leads to the building of a 3D structure (Figure 3C). One

that can both exhibit programmed deformation (e.g., self- limitation of inkjet printing is the relatively narrow range

expansion and self-compression) and endure bear-loading of materials, because using highly viscous inks may

environment have been developed for biomedical uses, increase the risk of nozzle blockage. However, because

such as artificial bone, cardiovascular stent, and orthopedic the fabrication unit includes single liquid droplets, the

apparatus . printing resolution of inkjet can be as high as micrometers

[35]

when appropriate materials and fine nozzles are used [37,38] .

2.2.3. 3D inkjet printing Due to the high-resolution and pinpointing deposition

Inkjet printing is a binder jetting technique used to print of droplets with a small volume, inkjet 3D printing is

computer data or information on paper . In recent years, widely used to produce smart constructs. For example,

[36]

Volume 9 Issue 1 (2023) 234 https://doi.org/10.18063/ijb.v9i1.638