Page 130 - IJB-9-2

P. 130

International Journal of Bioprinting Design and manufacture of high-performance bone plate

Figure 2. Femoral prosthesis. (A) Reverse reconstruction. (B) Substantiation. (C) Simulated repair of fracture.

Figure 3. Schematic diagram of the femoral prosthesis restraint and load application.

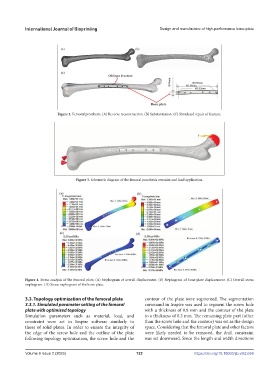

Figure 4. Stress analysis of the femoral plate. (A) Nephogram of overall displacement. (B) Nephogram of bone plate displacement. (C) Overall stress

nephogram. (D) Stress nephogram of the bone plate.

3.3. Topology optimization of the femoral plate contour of the plate were segmented. The segmentation

3.3.1. Simulated parameter setting of the femoral command in Inspire was used to segment the screw hole

plate with optimized topology with a thickness of 0.8 mm and the contour of the plate

Simulation parameters such as material, load, and to a thickness of 0.2 mm. The remaining plate part (other

constraint were set in Inspire software similarly to than the screw hole and the contour) was set as the design

those of solid plates. In order to ensure the integrity of space. Considering that the femoral plate and other factors

the edge of the screw hole and the outline of the plate were likely needed to be removed, the draft constraint

following topology optimization, the screw hole and the was set downward. Since the length and width directions

Volume 9 Issue 2 (2023) 122 https://doi.org/10.18063/ijb.v9i2.658