Page 22 - IJB-9-2

P. 22

International Journal of Bioprinting Extrusion-based biomaterial inks

engineering according to the mechanical performance. To

compensate for the absence of bioactive property, bioinert

PCL is conjugated to tissue-specific peptides, such as

bone morphogenetic protein mimetic peptide, glycine-

histidine-lysine peptide, and osteogenic growth peptide,

to promote chondrogenic or osteogenic differentiation of

stem cells [176,177] .

4.2. Chemical modification

Chemical modification of biomaterial ink is usually

intended to form stronger intermolecular interactions

that are related to its viscoelastic properties and perform

more chemical functionalities, thereby improving

the biocompatibility, printability, and mechanical

properties . The well-described chemical modifications

[31]

include thiolation, norbornene, and methacrylation that

Figure 6. Modification of biomaterial inks.

could create more functional derivatives. Photocurable

constructs, there are several general and specific challenges gelatin-based hydrogels, such as GelMA, are powerful

in the application of the ink. Mechanical properties usually light-responsive bioinks with adjustable hardness, excellent

[178]

need to be well tuned and matched to ensure specific biocompatibility, and printability . Norbornene-

functional requirements of various cells, tissues, or organs. functionalized gelatin (GelNB) mixed with a thiolated

Alginate can be printed into 3D tissue structure with crosslinker have recently gained increasing importance

relatively high printability by pre-crosslinking or coaxial as thiol-ene functional hydrogel systems. Methacrylated

nozzle-assisted crosslinking. Its surface modifications hyaluronic acid and norbornene-functionalized hyaluronic

should be paid close attention as they can affect mechanical acid were also used as inks in in situ photocrosslinking

[24]

properties, which vary greatly according to solution bioprinting . In another case, thiolated hyaluronic acid-

concentration and curing strategies, and immobilize cell based bioink-encapsulated marrow-derived mesenchymal

viability and interaction capabilities with the biomaterial stromal cells were printed in scaffold structure with

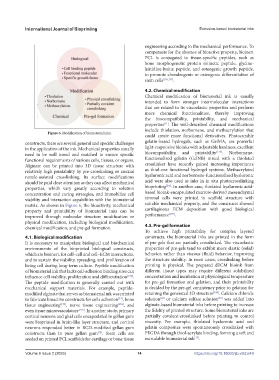

matrix. As shown in Figure 6, the bioactivity, mechanical suitable mechanical property, and the constructs showed

property and printability of biomaterial inks can be cartilaginous ECM deposition with good biological

[179]

improved through molecular structure modification or performance .

physical modification, including biological modification,

chemical modification, and pre-gel formation. 4.3. Pre-gel formation

To achieve high printability for complex layered

4.1. Biological modification constructs, the biomaterial inks are printed in the form

It is necessary to manipulate biological and biochemical of pre-gels that are partially crosslinked. The viscoelastic

environments of the bioprinted biological constructs, properties of pre-gels tend to exbibit more elastic (solid)

which are bioinert, for cell–cell and cell–ECM interactions, behavior, rather than viscous (fluid) behavior, improving

and to sustain the viability, spreading, and proliferation of the structure stability. In most cases, crosslinking before

living cell during long-term culture. Peptide modification printing is physical. The prepared dECM bioink from

of biomaterial ink that lacks cell-adhesion binding sites can different tissue types may require different solubilized

influence cell viability, proliferation and differentiation [172] . concentration and incubation at physiological temperature

The peptide modification is generally carried out with for pre-gel formation and gelation, and their printability

mechanical support materials. For example, peptide- is decided by the pre-gel consistency prior to gelation for

modified alginate that serves as biomaterial ink was printed retaining the generated 3D structure [180] . Calcium chloride

to fabricate bioactive constructs for cells adhesion , bone solution or calcium sulfate solution was added into

[50]

[51]

[29]

tissue engineering [173] , nerve tissue engineering [174] , and alginate-based biomaterial inks before printing to increase

even tissue microvasculature [175] . In another study, primary the fidelity of printed structure. Some biomaterial inks are

cortical neurons and glial cells encapsulated in gellan gum partially covalent-crosslinked before printing to control

were bioprinted in brain-like layer structure, and cortical viscosity. For example, thiolated hyaluronic acid and

neurons responded better in RGD-modified gellan gum gelatin composites were spontaneously crosslinked with

constructs than in pure gellan gum . Stem cells are PEGDA through thiol-acrylate binding, forming a soft and

[72]

[37]

seeded on printed PCL scaffolds for cartilage or bone tissue extrudable biomaterial ink .

Volume 9 Issue 2 (2023) 14 https://doi.org/10.18063/ijb.v9i2.649