Page 160 - IJB-9-3

P. 160

International Journal of Bioprinting LPBF of AKM/PEEK biological composite

Table 3. Crystallinity of AKM/PEEK composite specimens

ω (AKM = 0 wt%) ω (AKM = 5 wt%) ω (AKM = 10 wt%) ω (AKM = 15 wt%)

∆H (J/g) 45.20 37.85 34.45 32.40

m

X (%) 34.77 29.12 26.50 24.92

c

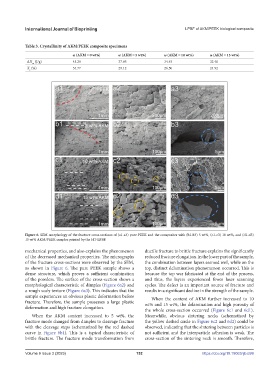

Figure 6. SEM morphology of the fracture cross-sections of (a1-a3) pure PEEK and the composites with (b1-b3) 5 wt%, (c1-c3) 10 wt%, and (d1-d3)

15 wt% AKM/PEEK samples printed by the HT-LPBF.

mechanical properties, and also explains the phenomenon ductile fracture to brittle fracture explains the significantly

of the decreased mechanical properties. The micrographs reduced fracture elongation. In the lower part of the sample,

of the fracture cross-sections were observed by the SEM, the combination between layers seemed well, while on the

as shown in Figure 6. The pure PEEK sample shows a top, distinct delamination phenomenon occurred. This is

dense structure, which proves a sufficient combination because the top was fabricated at the end of the process,

of the powders. The surface of the cross-section shows a and thus, the layers experienced fewer laser scanning

morphological characteristic of dimples (Figure 6a2) and cycles. The defect is an important source of fracture and

a rough scaly texture (Figure 6a3). This indicates that the results in a significant decline in the strength of the sample.

sample experiences an obvious plastic deformation before When the content of AKM further increased to 10

fracture. Therefore, the sample possesses a large plastic wt% and 15 wt%, the delamination and high porosity of

deformation and high fracture elongation. the whole cross-section occurred (Figure 6c1 and 6d1).

When the AKM content increased to 5 wt%, the Meanwhile, obvious sintering necks (schematized by

fracture mode changed from dimples to cleavage fracture the yellow dashed circle in Figure 6c2 and 6d2) could be

with the cleavage steps (schematized by the red dashed observed, indicating that the sintering between particles is

curve in Figure 6b1). This is a typical characteristic of not sufficient and the interparticle adhesion is weak. The

brittle fracture. The fracture mode transformation from cross-section of the sintering neck is smooth. Therefore,

Volume 9 Issue 3 (2023) 152 https://doi.org/10.18063/ijb.699