Page 301 - IJB-9-3

P. 301

International Journal of Bioprinting 3D bioprinting as a prospective therapeutic strategy for LSCD

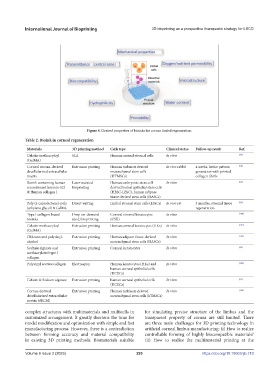

Figure 4. Desired properties of bioinks for cornea limbal regeneration.

Table 2. Bioink in corneal regeneration

Materials 3D printing method Cells type Clinical status Follow-up result Ref.

Gelatin-methacryloyl SLA Human corneal stromal cells In vitro [97]

(GelMA)

Corneal stroma-derived Extrusion printing Human turbinate derived In vivo rabbit 4 weeks, lattice pattern [98]

decellularized extracellular mesenchymal stem cells generation with printed

matrix (HTMSCs) collagen fibrils

Bioink containing human Laser-assisted Human embryonic stem cell In vitro [64]

recombinant laminin-521 bioprinting derived limbal epithelial stem cells

& Human collagen I (HESC-LESC), human adipose

tissue derived stem cells (HASCs)

Poly (ε-caprolactone)-poly Direct writing Limbal stromal stem cells (LSSCs) In vivo rat 3 months, stromal tissue [99]

(ethylene glycol) & GelMa regeneration

Type I collagen-based Drop-on-demand Corneal stromal keratocytes In vitro [100]

bioinks (dod) bioprinting (CSK)

Gelatin-methacryloyl Extrusion printing Human corneal keratocytes (HKs) In vitro [101]

(GelMA)

Chitosan and polyvinyl- Extrusion printing Human adipose tissue-derived In vitro [102]

alcohol mesenchymal stem cells (HASCs)

Sodium alginate and Extrusion printing Corneal keratocytes In vitro [65]

methacrylated type I

collagen

Polyvinyl acetate/collagen Electrospun Human keratocytes (HKs) and In vitro [103]

human corneal epithelial cells

(HCECs)

Gelatin & Sodium alginate Extrusion printing human corneal epithelial cells In vitro [63]

(HCECs)

Cornea-derived Extrusion printing Human turbinate derived In vitro [104]

decellularized extracellular mesenchymal stem cells (hTMSCs)

matrix (dECM)

complex structures with multimaterials and multicells in for simulating precise structure of the limbus and the

customized arrangement. It greatly shortens the time for transparent property of cornea are still limited. There

model modification and optimization with simple and fast are three main challenges for 3D printing technology in

manufacturing process. However, there is a contradiction artificial corneal limbus manufacturing: (i) How to realize

between forming accuracy and material compatibility controllable forming of highly biocompatible materials?

in existing 3D printing methods. Biomaterials suitable (ii) How to realize the multimaterial printing at the

Volume 9 Issue 3 (2023) 293 https://doi.org/10.18063/ijb.710