Page 455 - IJB-9-5

P. 455

International Journal of Bioprinting 3D-printed oblique lumbar interbody cage

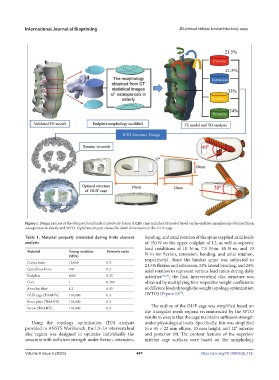

Figure 1. Design process of the oblique lateral lumbar interbody fusion (OLIF) cage included FE model based on the endplate morphology obtained from

osteoporosis in elderly and WTO. Right bottom part shows the detail dimensions of the OLIF cage.

Table 1. Material property simulated during finite element bending, and axial rotation of the spine (applied axial loads

analysis of 150 N on the upper endplate of L2, as well as separate

load conditions of 10 N-m, 7.5 N-m, 10 N-m, and 10

Material Young modulus Poisson’s ratio N-m for flexion, extension, bending, and axial rotation,

(MPa)

Cortex bone 12,000 0.3 respectively). Since the lumbar spine was subjected to

21.5% flexion and extension, 33% lateral bending, and 24%

Cancellous bone 100 0.2 axial rotation to represent various load ratios during daily

Endplate 4000 0.25 activities [23,24] , the final intervertebral disc structure was

Core 1 0.499 obtained by multiplying four respective weight coefficients

Annulus fiber 4.2 0.45 of different loads through the weight topology optimization

[16]

OLIF cage (Ti6Al4V) 110,000 0.3 (WTO) (Figure 1) .

Bone plate (Ti6Al4V) 110,000 0.3

Screw (Ti6Al4V) 110,000 0.3 The outline of the OLIF cage was simplified based on

the triangular mesh regions recommended by the WTO

results to ensure that the cage maintains sufficient strength

Using the topology optimization (TO) analysis under physiological loads. Specifically, this was simplified

provided in ANSYS Workbench, the L3–L4 intervertebral to a 45 × 22 mm ellipse, 10 mm height, and 12° anterior

disc region was designed to optimize individually the and posterior tilt. The contour features of the superior/

structure with sufficient strength under flexion, extension, inferior cage surfaces were based on the morphology

Volume 9 Issue 5 (2023) 447 https://doi.org/10.18063/ijb.772