Page 292 - IJB-9-6

P. 292

International Journal of Bioprinting Progress in bioprinted ear reconstruction

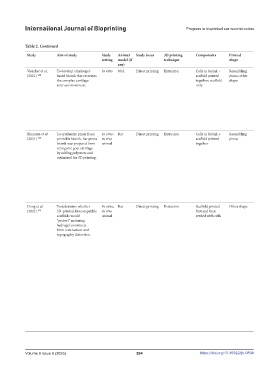

Table 2. Continued

Study Aim of study Study Animal Study focus 3D printing Components Printed Printed Cell nature/type Notable post- Assessment Findings Limitations and suggested

setting model (if technique shape material printing of success/ improvements

any) modifications integration

Visscher et al. To develop a hydrogel- In vitro N/A Direct printing Extrusion Cells in bioink + Resembling Bioink Porcine ear UV crosslinking Histopathology; • A photo-crosslinkable cartilage-derived In vitro only

(2021) [28] based bioink that recreates scaffold printed pinna; other cartilage after printing mechanical ECM-based bioink was successfully developed • Large protein

the complex cartilage together; scaffold shape testing; other for auricular cartilage reconstruction and heterogeneity observed

microenvironment. only such as mass supported the activity and maturation of between samples in

spectrometry chondrocytes in bioprinted constructs. the mass spectrometric

proteome • Decellularized cartilage-derived ECM can be analyses, which makes

analysis used for cell-based 3D bioprinting. it difficult to draw a

• The inclusion of gelatin, HA, and glycerol specific conclusion

improved printability and initial structural on effects of protein

integrity, while UV polymerization increased abundance on growth

stiffness.

• The stiffness of the gel may affect cell

behavior.

Bhamare et al. To synthesize pinna from In vitro; Rat Direct printing Extrusion Cells in bioink + Resembling Bioink Goat cartilage used Ethylene oxide Histopathology; • The ear had biodegradable properties despite Small study in animals only

(2021) [26] printable bioink. Ear pinna in vivo scaffold printed pinna in bioink used to sterilize ultrasound containing polymers.

bioink was prepared from animal together scaffold before scan; micro- • Mechanical strength of 3D-printed pinna

xenogenic goat cartilage implantation. It was CT scan; showed similar results like normal ear pinna.

by adding polymers and trimmed into pieces mechanical • Pinna was biocompatible (in ovo and in

optimized for 3D printing. (10 mm in width), testing vivo) having newly developed chondrocytes,

and rinsed with elastin fibers, progenitor cells of ECM after

saline containing transplantation.

antibiotic solution. • Within 30 days, the transplanted 3D-printed

pinna regenerated chondrocytes, GAG,

elastin fibers, collagen, and retained its ECM.

• The occurrence of angiogenesis after grafting

showed that the 3D-printed ear pinna was

accepted by the rat ear and had non-toxic

properties similar to those of a native ear pinna.

Dong et al. To determine whether In vitro; Rat Direct printing Extrusion Scaffold printed Other shape PLA Bovine auricular Chondrocytes in Histopathology • Scaffolds were fabricated using injection Using bovine cells is a

(2021) [10] 3D-printed, biocompatible in vivo first and then chondrocytes collagen hydrogels molding to protect auricular cartilage necessary step toward

scaffolds would animal seeded with cells were added to the constructs from external compression and eventually using human

“protect” maturing printed constructs. intrinsic contractile forces, resulting in cells to produce clinically

hydrogel constructs Cell-loaded significant reduction of contraction and translatable results. Using

from contraction and constructs were preservation of complex topography. a rodent model is limiting

topography distortion. cultured in DMEM • Injection molding allows for the creation of a because the loose nature

overnight before more fully interconnected porous network and of rodent skin does not

implantation. is particularly effective for quickly producing accurately replicate

homogenous volumes with high accuracy. the compressive forces

• Mechanically attaching a cell-seeded collagen experienced by scaffolds

construct to an external structure helps under human auricular or

maintain shape retention during extended scalp skin.

culture in vitro.

• Larger (12-mm wide) porous PLA discs

featuring a ridge on the surface were designed

to simulate the shape of the helical rim and

compensate for anticipated contraction,

blunting, and distortion. After 3 months

in vivo, the helical rim feature was better

preserved in the injection molded (SInj) and

scaffolded (S) groups compared to the naked

(N) group, which lost the rim feature and

became a flat disc of cartilage.

• The presence of an external PLA scaffold did

not hinder the formation of healthy cartilage

within the constructs.

Volume 9 Issue 6 (2023) 284 https://doi.org/10.36922/ijb.0898